In the ever-evolving world of IT infrastructure, the adoption of hyperconverged infrastructure (HCI) has emerged as a transformative solution for businesses seeking efficiency, scalability, and simplified management. This article delves into the realm of HCI, exploring its definition, advantages, its impact on data centers, and recommendations for the best infrastructure switch for small and medium-sized businesses (SMBs).

What Is Hyperconverged Infrastructure?

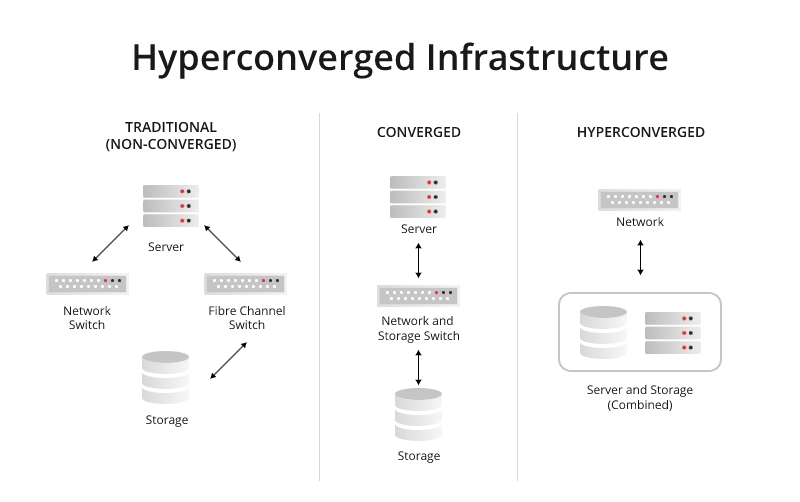

Hyperconverged infrastructure (HCI) is a type of software-defined infrastructure that tightly integrates compute, storage, networking, and virtualization resources into a unified platform. Unlike traditional data center architectures with separate silos for each component, HCI converges these elements into a single, software-defined infrastructure. HCI’s operation revolves around the integration of components, software-defined management, virtualization, scalability, and efficient resource utilization to create a more streamlined, agile, and easier-to-manage infrastructure compared to traditional heterogeneous architectures.

Benefits of Hyperconverged Infrastructure

Hyperconverged infrastructure (HCI) offers several benefits that make it an attractive option for modern IT environments:

Simplified Management: HCI consolidates various components (compute, storage, networking) into a single, unified platform, making it easier to manage through a single interface. This simplifies administrative tasks, reduces complexity, and saves time in deploying, managing, and scaling infrastructure.

Scalability: It enables seamless scalability by allowing organizations to add nodes or resources independently, providing flexibility in meeting changing demands without disrupting operations.

Cost-Efficiency: HCI often reduces overall costs compared to traditional infrastructure by consolidating hardware, decreasing the need for specialized skills, and minimizing the hardware footprint. It also optimizes resource utilization, reducing wasted capacity.

Increased Agility: The agility provided by HCI allows for faster deployment of resources and applications. This agility is crucial in modern IT environments where rapid adaptation to changing business needs is essential.

Better Performance: By utilizing modern software-defined technologies and optimizing resource utilization, HCI can often deliver better performance compared to traditional setups.

Resilience and High Availability: Many HCI solutions include built-in redundancy and data protection features, ensuring high availability and resilience against hardware failures or disruptions.

Simplified Disaster Recovery: HCI simplifies disaster recovery planning and implementation through features like data replication, snapshots, and backup capabilities, making it easier to recover from unexpected events.

Support for Virtualized Environments: HCI is well-suited for virtualized environments, providing a robust platform for running virtual machines (VMs) and containers, which are essential for modern IT workloads.

Best Hyperconverged Infrastructure Switch for SMBs

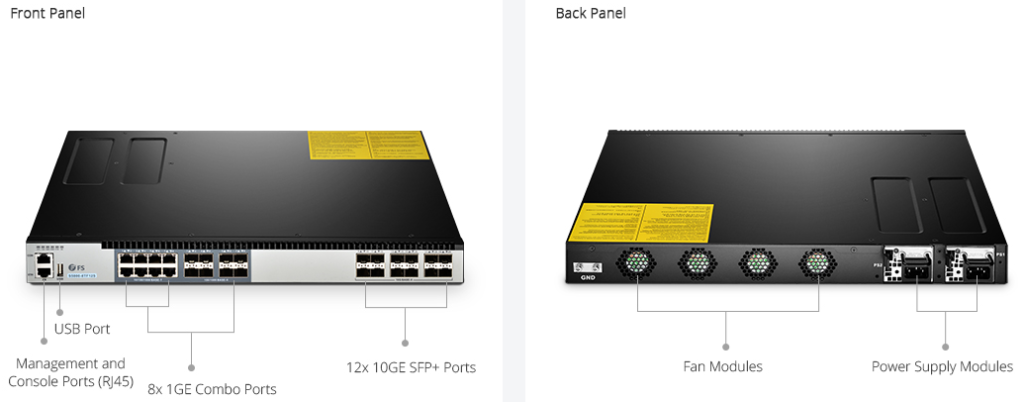

The complexity of traditional data center infrastructure, both hardware and software, poses challenges for SMBs to manage independently, resulting in additional expenses for professional services for setup and deployment. However, the emergence of hyperconverged infrastructure (HCI) has altered this landscape significantly. HCI proves highly beneficial and exceedingly suitable for the majority of SMBs. To cater for the unique demands for hyper-converged appliance, FS.com develops the S5800-8TF12S 10gb switch which is particularly aimed at solving the problems of access to the hyper-converged appliance of small and medium-sized business. With the abundant benefits below, it is a preferred key solution for the connectivity between hyper-converged appliance and the core switch.

Data Center Grade Hardware Design

FS S5800-8TF12S hyper-converged infrastructure switch provides high availability port with 8-port 1GbE RJ45 combo, 8-port 1GbE SFP combo and 12-port 10GbE uplink in a compact 1RU form factor. With the capability of static link aggregation and integrated high performance smart buffer memory, it is a cost-effective Ethernet access platform to hyper-converged appliance.

Reduced Power Consumption

With two redundant power supply units and four smart built-in cooling fans, FS S5800-8TF12S hyper-converged infrastructure switch provides necessary redundancy for the switching system, which ensures optimal and secure performance. The redundant power supplies can maximize the availability of the switching device. The heat sensors on the fan control PCBA (Printed Circuit Board Assembly) monitor and detect the ambient airs. It converts fans speeds accordingly to adapt to the different temperatures, thus reducing power consumption in proper operating temperatures.

Multiple Smart Management

Instead of being managed by Web interface, the FS S5800-8TF12S hyper-converged infrastructure switch supports multiple smart management with two RJ45 management and console ports. SNMP (Simple Network Management Protocol) is also supported by this switch. Thus when managing several switches in a network, it is possible to make the changes automatically to all switches. What about the common switches managed only by Web interface? It will be a nightmare when an SMB needs to configure multiple switches in the network, because there’s no way to script the push out of changes if not parse the web pages.

Traffic Visibility and Trouble-Shooting

In FS S5800-8TF12S HCI switch, the traffic classification is based on the combination of the MAC address, IPv4/IPv6 address, L2 protocol header, TCP/UDP, outgoing interface, and 802.1p field. The traffic shaping is based on interfaces and queues. Thus the traffic flow which are visible and can be monitored in real time. With the DSCP remarking, the video and voice traffic that is sensitive to network delays can be prioritized over other data traffic, so the smooth video streaming and reliable VoIP calls are ensured. Besides, the FS S5800-8TF12S switch comes with comprehensive functions that can help in trouble-shooting. Some basic functions include Ping, Traceroute, Link Layer Discovery Protocol (LLDP), Syslog, Trap, Online Diagnostics and Debug.

Conclusion

Hyperconverged infrastructure stands as a catalyst for IT transformation, offering businesses a potent solution to optimize efficiency, streamline operations, and adapt to ever-changing demands. By embracing HCI and selecting the right infrastructure components, SMBs can harness the power of integrated systems to drive innovation and propel their businesses forward in today’s dynamic digital landscape.

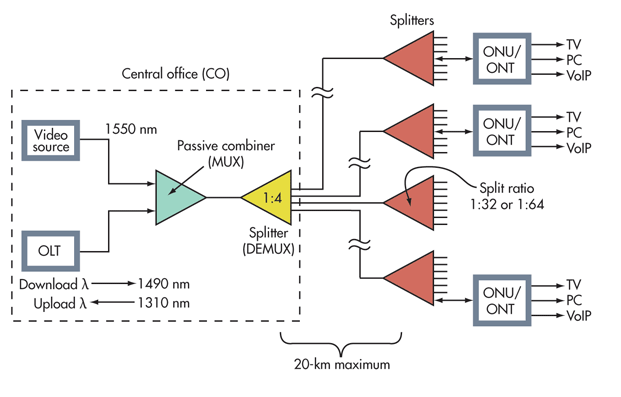

OLT: The optical line terminal is the main element of the network and it is usually placed in the Local Exchange and it’s the engine that drives FTTH system. OLT has two float directions: one is upstream getting distributing different type of data and voice traffic from users, the other is downstream getting data, voice and video traffic from metro network or from a long-haul networkand sending it to all ONT modules on the optical distribution network (ODN). The picture on the left shows an OLT.

OLT: The optical line terminal is the main element of the network and it is usually placed in the Local Exchange and it’s the engine that drives FTTH system. OLT has two float directions: one is upstream getting distributing different type of data and voice traffic from users, the other is downstream getting data, voice and video traffic from metro network or from a long-haul networkand sending it to all ONT modules on the optical distribution network (ODN). The picture on the left shows an OLT. ONU/ONT: Optical network terminals or units are deployed at customer’s premises. ONTs are connected to the OLT by means of optical fiber and no active elements are present in the link. A single ONT can serve as point of access for one or multiple customers and be deployed either at customer’s premises or on the street in a cabinet. The ONU usually communicates with an ONT, which may be a separate box that connects the PON to TV sets, telephones, computers, or a wireless router. The ONU or ONT can be the same device. The picture on the right shows an ONT.

ONU/ONT: Optical network terminals or units are deployed at customer’s premises. ONTs are connected to the OLT by means of optical fiber and no active elements are present in the link. A single ONT can serve as point of access for one or multiple customers and be deployed either at customer’s premises or on the street in a cabinet. The ONU usually communicates with an ONT, which may be a separate box that connects the PON to TV sets, telephones, computers, or a wireless router. The ONU or ONT can be the same device. The picture on the right shows an ONT.

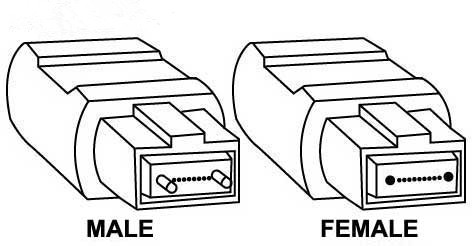

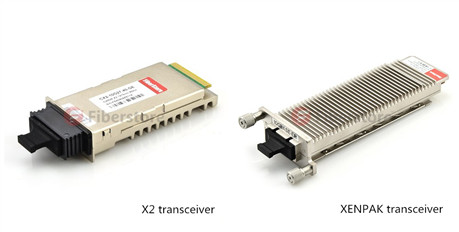

XENPAK transceiver is a pluggable transceiver for 10Gbps applications, specifically 10 Gigabit Ethernet. The electrical interface is called XAUI, which provides four 2.5Gbps signals to the transmitter, which multiplexes or serialize them into a single 10Gbps signal to drive the source. It uses a 70-pin electrical connector. The optical interface is usually a duplex SC.

XENPAK transceiver is a pluggable transceiver for 10Gbps applications, specifically 10 Gigabit Ethernet. The electrical interface is called XAUI, which provides four 2.5Gbps signals to the transmitter, which multiplexes or serialize them into a single 10Gbps signal to drive the source. It uses a 70-pin electrical connector. The optical interface is usually a duplex SC.