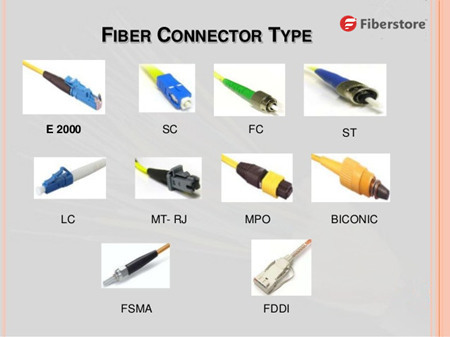

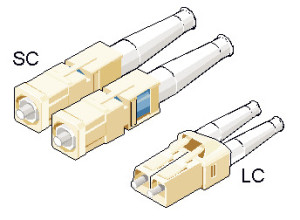

With the rapid development of fiber networks, fiber connectors have become an essential assembly to cater for high-performance fiber optic system. There are various fiber connector types in the market, such as LC, ST, SC, MPO/MTP and so on, among which, SC is one of the most commonly used fiber connectors. Further Classifying SC by polishing type, we have SC APC connector and SC UPC connector. This article will introduce SC APC vs SC UPC and illustrate their difference for your selection guide.

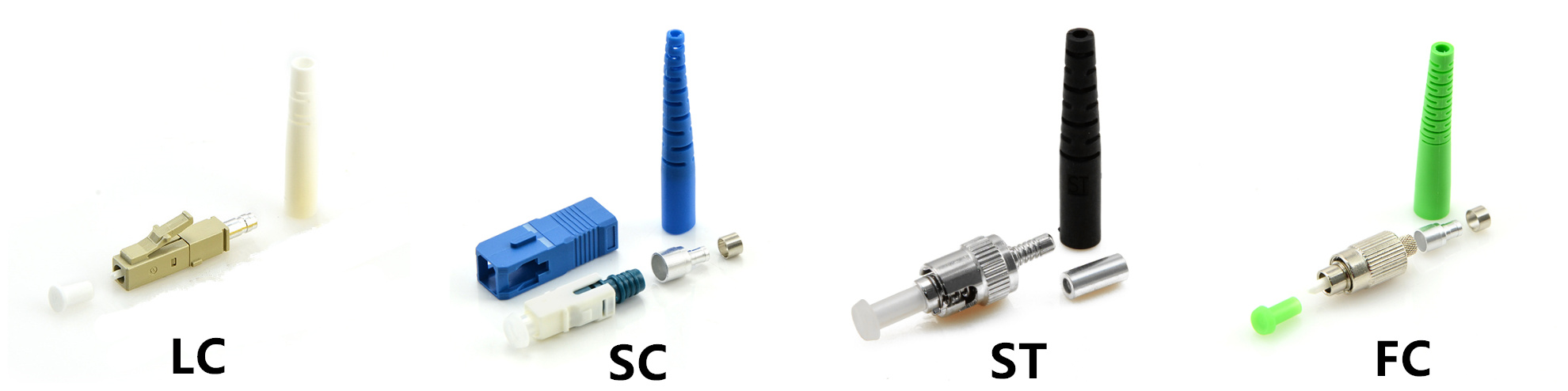

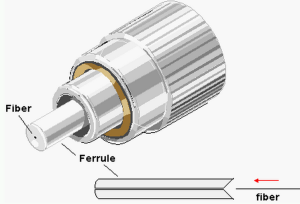

SC is the abbreviation of Subscriber Connector, sometimes also refers to Square Connector or Standard Connector. SC is a type of fiber optic connector with snap (push-pull coupling) coupling type and a 2.5 mm diameter ferrule, which is popularly used in single mode duplex system for its high performance and accurate alignment.

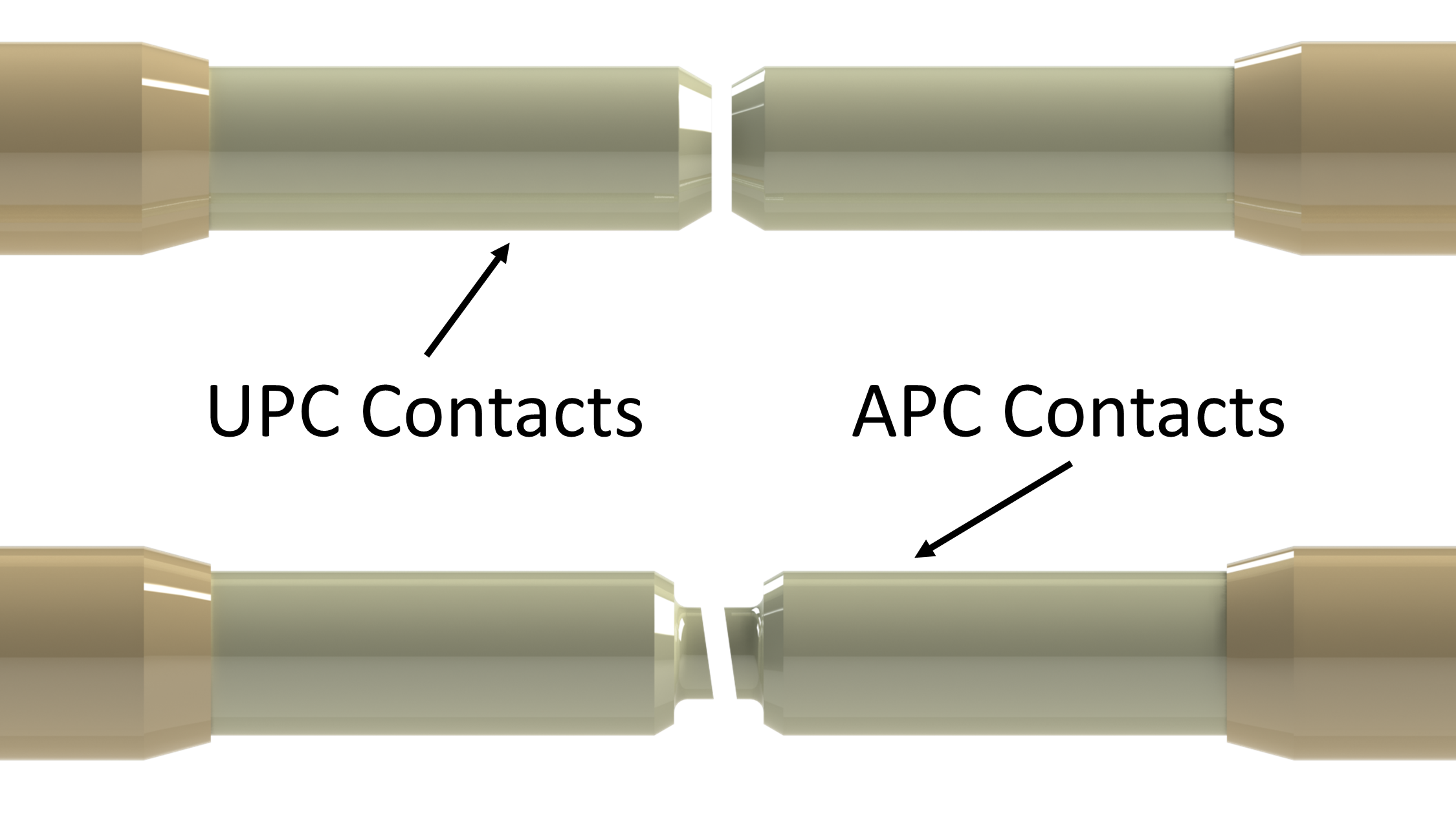

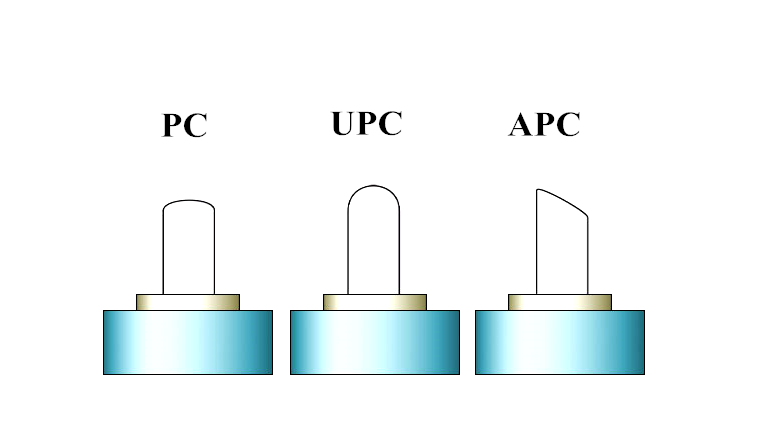

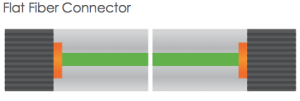

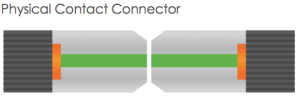

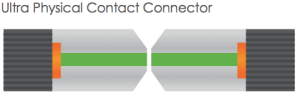

Generally speaking, SC APC connector and SC UPC connector are distinct from each other based on fiber end face. SC APC connector is polished with an 8-degree angle, while SC UPC connector is polished with no angle, which causes difference in light reflection. SC UPC connector adopts an extended polish method to realize finer fiber surface finish, which brings much lower back reflection (ORL) and thus provides much more reliable signal in data center, digital TV and telephone. Although SC UPC connector has low insertion loss and wide range of application, there are some applications requiring for higher return loss, no less than 60 dB or even higher. In this circumstance, SC APC connector can make the need and consistently perform well due to the 8-degree angle.

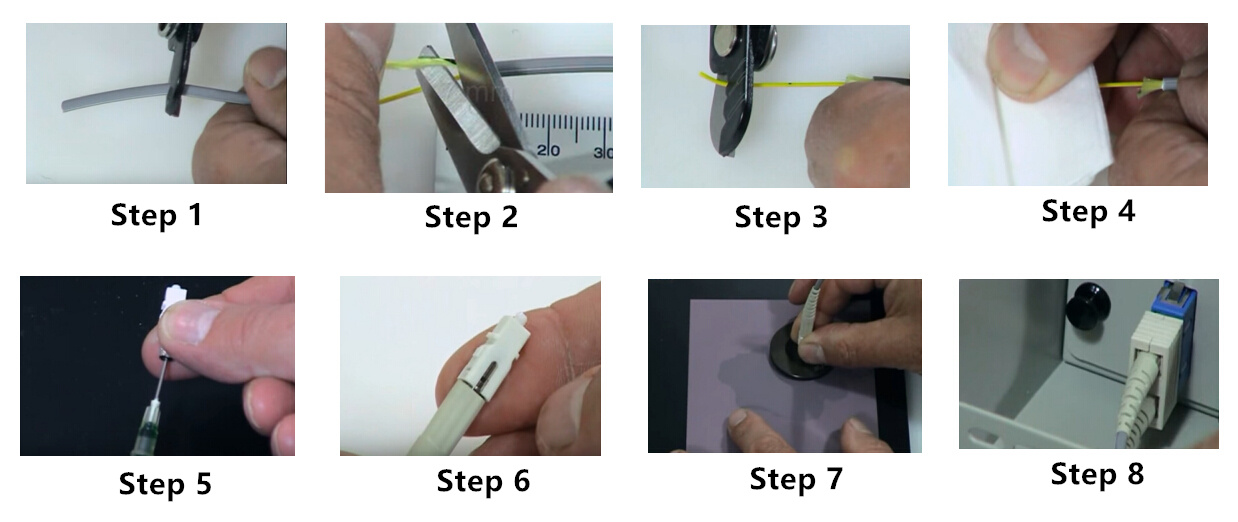

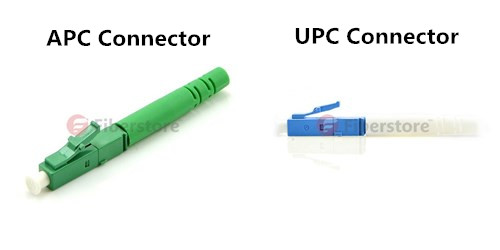

Figure 1: This photo shows a SC APC connector.

As mentioned above, we know SC APC and SC UPC varies from polishing style, which is a difference in the manufacturing process. But in the actual usage, what are the distinct features of SC APC and SC UPC connectors and how to choose from them? Here are some clues.

With a SC UPC connector installed on the end of a fiber, reflected light is reflected straight back to the light source. However, with a SC APC connector, reflected light is reflected at an angle into the outer cladding layer rather than straight back towards the light source. This different way of reflection of reflected lights brings about different return loss value. SC APC connector is standardized with a return loss value as -60dB or higher, while SC UPC connector as -50dB or higher.

Another specification to consider about fiber connector is insertion loss. Lower the insertion loss, better the performance. Someone prefer SC UPC connector, because they hold the view that SC UPC connector is easier to realize low insertion. This is true on account of less air gaps in SC UPC connector than SC APC connector. However, modern technique has made insertion loss value of SC APC connector as low as SC UPC connector.

SC APC connector is commonly used in applications that are much more sensitive to return loss, and requires for high precision signal, such as FTTX (Fiber To The X), video delivery through RF signal, WDM (wavelength division multiplexing) applications and analogue equipment like CCTV. For applications less sensitive to return loss and no other particular demands are required, a SC UPC connector can work as equal effectively as a SC APC connector.

Figure 2: This photo shows a SC UPC connector.

While SC APC connector is green, SC UPC connector is blue. Besides, the first is much more expensive than the latter one for the optical performance of SC APC much better than SC UPC connector. Other factors to think is the ease of use and your personal needs.

This article touches the concept of several items: SC, APC connector and UPC connector. Then it explains why SC APC connector is distinct from SC UPC connector from several aspects. It is improper to say one SC connector type wins the other for there are lots of consideration under specific circumstances. Simply put, people choose from these two SC connectors according to their personal need. Taking the factors of optical performance, cost and application in usage into consideration, one can make the best choice.