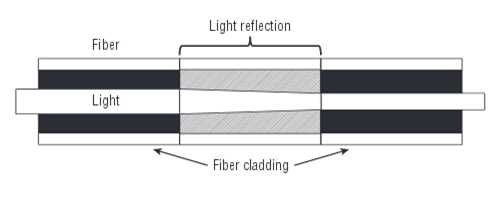

PLC splitter or planar lightwave circuit splitter is a passive component that has the special waveguide made of planar silica, quartz or other materials. It is employed to split a strand of optical signal into two or more strands. PLC splitter also has lots of split ratios, and the most common ones are 1:8, 1:16, 1:32, 1:64, 2:8, 2:16, 2:32 and 2:64. Products usually accord with Telcordia GR-1209-CORE, Telcordia GR-1221-CORE.YD/T1117-2001 standards. There are many types of PLC splitters to meet with different needs in OLT and ONT connection and splitting of optical signals over FTTH passive optical networks.

PLC splitter is especially important in FTTH networks, which shares a single PON network with many subscribers. Having no electronics and power in PLC splitter, it is very cost-effective to provide reliable light distribution solutions. Unlike FBT (fused biconical taper) splitter, PLC splitter has a better performance that offers accurate splits with minimal loss in an efficient package. Some typical types are widely used in optical network applications, i.e. bare fiber splitter, blockless splitter, ABS splitter, fan-out splitter, tray type splitter, rack-mount splitter, LGX splitter and mini plug-in type splitter.

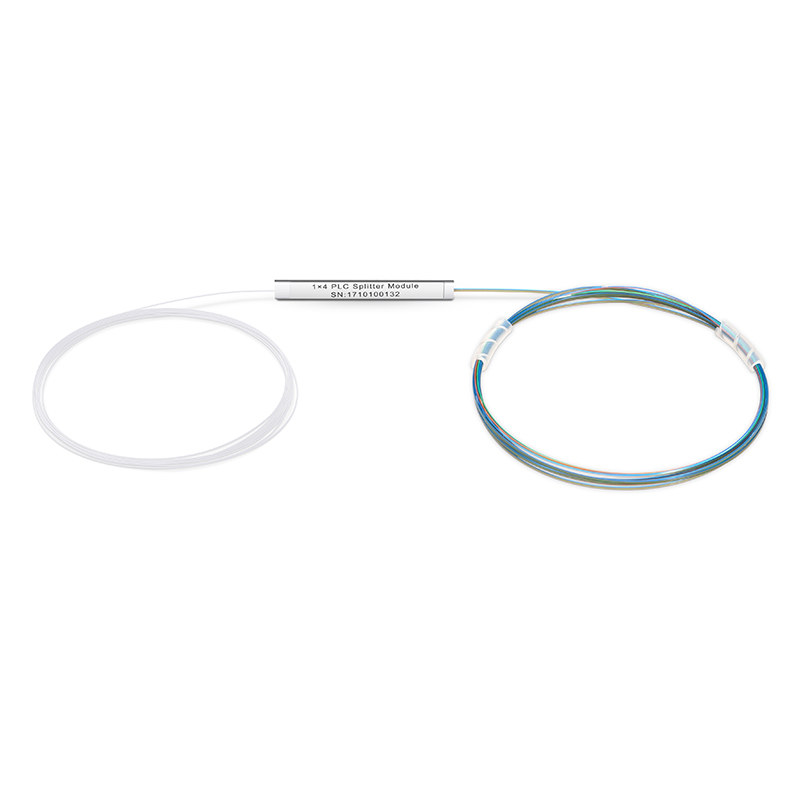

Bare fiber PLC splitter has no connector at the bare fiber ends. It can be spliced with other optical fibers in the pigtail cassette, test instrument and WDM system, which minimizes the space occupation. It is commonly used for FTTH, PON, LAN, CATV, test equipment and other applications.

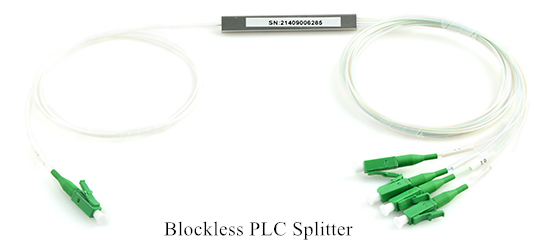

Likewise, blockless PLC splitter has a similar appearance as bare PLC splitter. But it has a more compact stainless tube package which provides stronger fiber protection, and its fiber ends are all terminated with fiber optic connectors. Connectors are commonly available with SC, LC, FC and ST types. Thus, there is no need for fiber splicing during installation. Blockless PLC splitter is mainly used for different connections over distribution boxes or network cabinets.

ABS PLC splitter has a plastic ABS box to protect the PLC splitter to adapt to different installation environments and requirements. Common splitter modules are 1×4, 1×8, 1×16, 1×32, 1×64, 2×4, 2×8, 2×16, 2×32. It is widely used with outdoor fiber distribution box for PON, FTTH, FTTX, PON, GOPN networks.

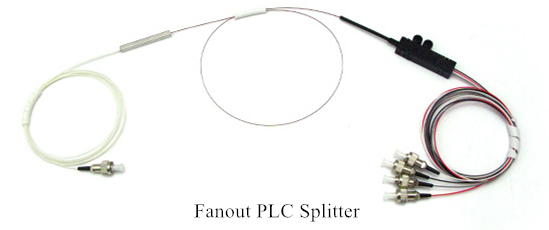

PLC splitter with fan-out is mainly used for 0.9mm optical fiber where the ribbon fiber can convert to 0.9mm optical fiber through fan-out. 1×2, 1×4, 1×8, 1×16, 1×32, 1×64, 2×2, 2×4, 2×8, 2×16, 2×32, 2×64 fanout types are all available with PLC splitters. Fiber adapters can also be used for the input and output ends of this kind of splitters to directly meet the demand on smaller size of splitters.

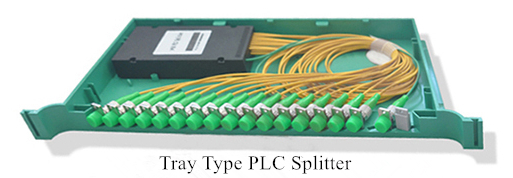

Tray type PLC splitter can be regarded the fiber enclosure which contains PLC fiber splitter inside a enclosure. It is often directly installed in optical fiber distribution box or optical distribution frame. FC, SC, ST & LC connectors are selective for termination. Tray type PLC splitter is an ideal solution for splitting at the places that are near OLT or ONU.

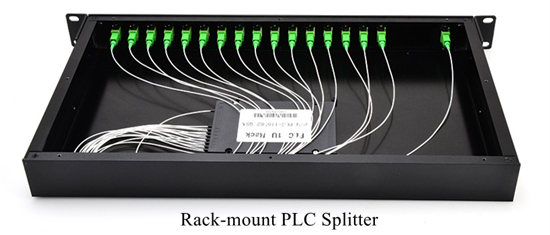

Rack-mount PLC splitter can be used for both indoor and outdoor applications in FTTx projects, CATV or data communication centers. It uses the 19-inch rack unit standard to contain the PLC splitter inside a rack unit.

LGX PLC splitter or LGX box PLC splitter has a strong metal box to house the PLC splitters. It can be used alone or be easily installed in standard fiber patch panel or fiber enclosure. The standard LGX metal box housing provides a plug-and-play method for integration in the network, which eliminates any risk during installation. No filed splicing or skilled personnel is required during deployment.

Similar to the LGX PLC splitter, mini plug-in PLC type splitter is its small version with a compact design. It is usually installed in the wall mount FTTH box for fiber optic signal distribution. Using the mini plug-in PLC type splitter saves time and space but still provides reliable protection for the fiber optic splitter.

These types of PLC splitters are typically installed to serve for PON and FTTH networks. 1xN and 2xN are the common splitter ratios for specific applications. You should choose the most suitable one according to your project. Hope this article provides some help.

Source:

How Many Fiber Optic Splitter Types Are There? – FS Community