Multimode fiber has been highly favored by Ethernet users and gained the widest acceptance in network backbones where it has offered users the opportunity to extend link distances, increase network reliability, and lower costs by centralizing electronics. OM3 fiber emerges just at the right time. The predominance of OM3 fiber is that utilizes laser-optimized fiber, which is the highest-capacity medium for short-wave 10G optical transmission. OM4 fiber just joined multimode fiber family after OM3 fiber in order to meet the requirement of longer range applications. This passage would give a brief introduction to OM3 and OM4 fiber, give a further analysis on their differences and selection guide, as well as list their applications.

Introduction to OM3 & OM4 Fiber

Both OM3 and OM4 fiber meet the ISO 11801 standard. The standard specifies that OM3 fibers are capable of 10 Gb/s performance over distances of up to 300m. Like being mentioned, the laser optimized 50/125 mm multimode OM3 fiber is of predominance, which provides sufficient bandwidth to support 10 GbE and beyond with cable lengths up to 550 meters. OM4 fiber is a further improvement to OM3 fiber. It also uses a 50µm core but it supports 10 Gigabit Ethernet at lengths up 550 meters and it supports 100 Gigabit Ethernet at lengths up to 150 meters.

Main Difference Between OM3 And OM4 Fiber

Attenuation is caused by losses in light through the passive components, such as cables, cable splices, and connectors. Attenuation is the reduction in power of the light signal as it is transmitted (dB). The maximum attenuation of OM3 and OM4 fiber allowed at 850nm: OM3<3.5 dB/Km; OM4 <3.0 dB/Km. So it is obvious that OM4 fiber causes lower losses due to different construction.

As is known to most people, modal dispersion attaches great importance to bandwidth. The lower the modal dispersion, the higher the modal bandwidth and the greater the amount of information that can be transmitted. The minimum OM3 and OM4 fiber cable bandwidth at 850nm: OM3 2000 MHz·km; OM4 4700 MHz· km. The higher bandwidth available in OM4 means a smaller modal dispersion and thus allows the cable links to be longer or allows for higher losses through more mated connectors.

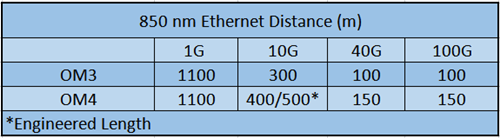

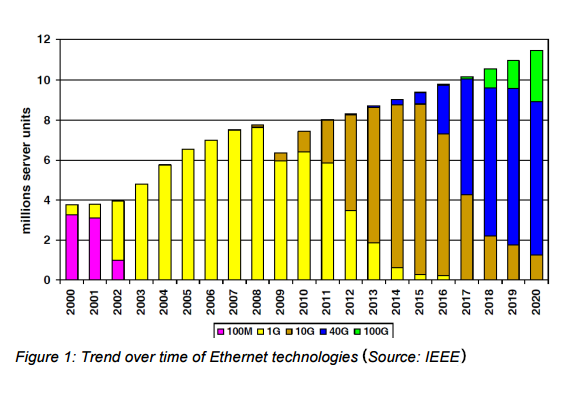

OM3 And OM4 Fiber 10G/40G/100G Transmission Distance

The maximum transmission distance of OM4 fiber is 400-550m (depending on module capability) while OM3 fiber can only be up to 300m. And thus, OM4 can tolerate a higher level of loss at distances between 200-300m as it is designed to operate at longer distances than OM3 fiber. It may be a more flexible option for network managers to install OM4 fiber within these instances. You can check difference between OM3 and OM4 in transmission distance in the following table.

OM3 And OM4 Fiber Price

In comparison to OM3 fiber, the cost for OM4 is higher due to the manufacture process and market fluctuations. In a large extent, cost depends on the construction type of the cable (loose tube, tight buffered, etc.). OM4 fiber cable is about twice as expensive as OM3 fiber cable. This means that the cost difference of lots of fiber products such as standard fiber patch panels, MTP cassette modules, fiber patch cords is very small (as the volume of cable is small).

OM3 And OM4 Fiber Selection Guide

Fifty micron OM3 fiber is designed to accommodate 10 Gigabit Ethernet up to 300 meters, and OM4 can accommodate it up to 550 meters. Therefore, many users are now choosing OM3 and OM4 over the other glass types. In fact, nearly 80% of 50 micron fiber sold is OM3 or OM4. If you require higher data rates or plan on upgrading your network in the near future, laser optimized 50 micron (OM3 or OM4) would be the logical choice. Compared to OM4, OM3 fiber is more future proofing for most applications, which allows speeds of 10 GB/s up to 100 GB/s. OM4 fiber provides users a transmission solution over longer distances and leaves more wiggle room in optical budgets.

OM3 and OM4 fiber cables are typically used in data center structured cabling environments running high speeds of 10G or even 40 or 100 Gigabit Ethernet, SAN (Storage Area Networking), Fiber Channel, FCOE (Fiber Channel Over Ethernet) with such manufacturers as Cisco, Brocade, EMC and others. Typical applications could be virtualized or internal cloud core data center applications. For 40G and 100G fiber cable applications, MTP/MPO cable would also be a great choice. MTP cabling assemblies (MTP/MPO trunk cable, MTP/MPO harness cable, MTP/MPO conversion cable, etc), with their overwhelming advantages, providing a fast, simple and economical upgrade path from 10 Gigabit to 40 or 100 Gigabit applications.

Conclusion

In this article, we mainly discussed OM3 fiber, OM4 fiber, their main differences, transmission guide and applications for 10G/40G/100G network. We put emphasis on OM3 and OM4 fiber 10G/40G/100G transmission distance and selection guide. OM3 and OM4 multimode fiber provide a cost effective solution for inside buildings or corporate campuses. Hope this article would be helpful for you to understand OM3 and OM4 fiber and to select right fiber cable for yourself.

as well as improved troubleshooting and reconfiguration during moves, adds and changes. Except for that, it has other advantages reflected in these sides:

as well as improved troubleshooting and reconfiguration during moves, adds and changes. Except for that, it has other advantages reflected in these sides: