Over the years, fiber optic connectors are no longer a deep concern for network installers. The industry standards of making connectors replaced the complex installation. A number of fiber optic connector types have been evolved and withstood the test of time to become industry standards. The main types of fiber optic connectors include: ST, FC, SC, and LC. These connectors come in many configurations and usages. This article touches on the very basics of fiber optic connectors types, market as well as its installation.

Fiber Optic Connector Type

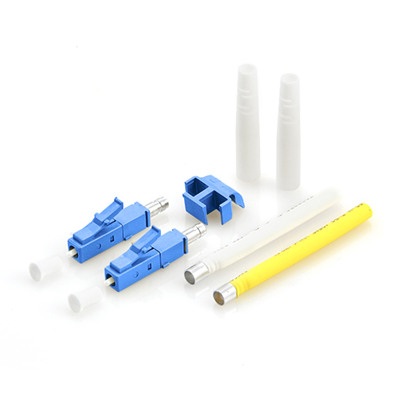

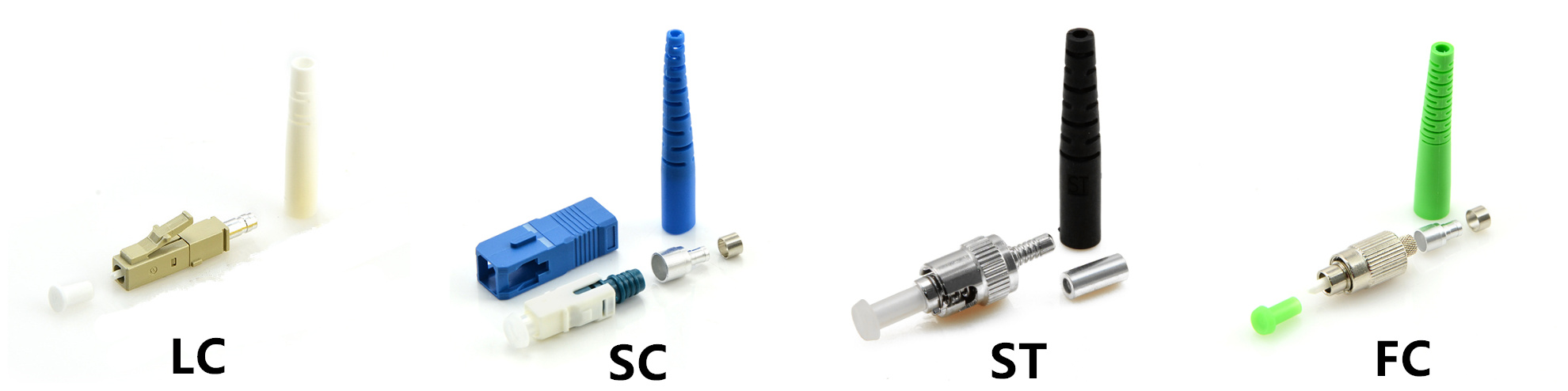

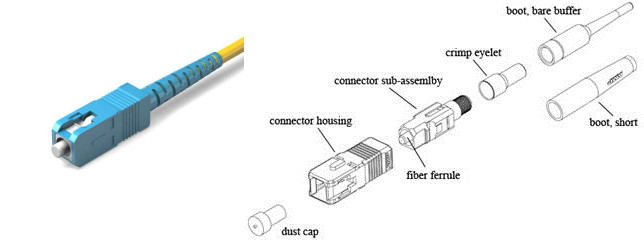

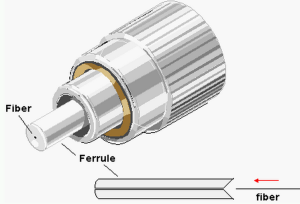

The common fiber optic connector types include ST, SC, FC, LC, MU, E2000, MTRJ, SMA, DIN as well as MTP & MPO etc. Each one has its own advantages, disadvantages, and capabilities. All fiber optic connectors have four basic components, which are the ferrule, connector body, cable, and coupling device. They have been widely used in the termination of fiber optic cables, such as fiber optic pigtail, fiber optic patch cables and so on. In this passage, we would mainly give brief introduction to the four most common fiber optic connector types.

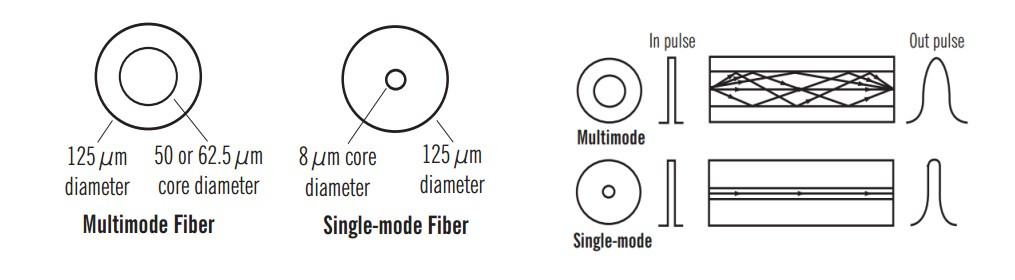

One most common of fiber optic connectors is the ST connector. This simplex fiber connector evolved from previous designs and was finally introduced by AT&T in the mid-late 1980s. It has become the de-facto standard in the security market and is commonly used in the AV market on such products as HDSDI, RGB/DVI, and others. It is available in both multimode and singlemode versions. The insertion loss of the ST connector is less than 0.5 dB, with typical values of 0.3 dB being routinely achieved. It is relatively easy to terminate in the field. Besides, it has good strain relief and good, but not exceptional attenuation characteristics.

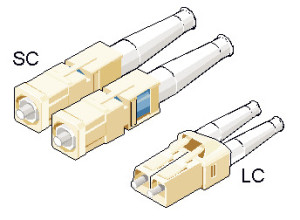

Developed by Lucent Technologies, the LC fiber optic connector has become the ubiquitous fiber optic connector for telecom applications. But LC connector does not stand for Lucent Connector. It is used in conjunction with small form pluggable (SFP) optical transceivers. These SFP devices are now becoming very common in Pro AV applications for such products as HDMI, DVI, audio, optical distribution amplifiers, optical/electrical/optical (OEO) switches, and so forth. The LC connector is smaller than all other connectors and is a push-pull design connector.

The SC fiber optic connectors are common in singlemode fiber optic telecom applications and analog CATV. Like the LC connector, this is also a push-pull design and is also commonly used in patch panels that act as the connector interface between the main field cable and smaller patch cords connected to the fiber transmission equipment. Some manufacturers of fiber AV equipment also use SC connectors in conjunction with their optical emitter and detector devices.

The FC fiber optic connector has become the connector of choice for singlemode fiber. It is mainly used in fiber optic instruments, singlemode fiber optic components, and high-speed fiber optic communication links. This high-precision, ceramic ferrule connector is equipped with an anti-rotation key, reducing fiber endface damage and rotational alignment sensitivity of the fiber. The key is also used for repeatable alignment of fibers in the optimal, minimal-loss position. Multimode versions of this connector are also available. The typical insertion loss of the FC connector is around 0.3 dB.

You can check the detailed specification of the above four fiber optic connectors on the below table.

| Connector Type | Singlemode (9/125) Insertion Loss (dB) | Multimode Insertion Loss (dB | Return Loss (dB) |

|---|---|---|---|

| ST Connector | ≤0.5 | ≤0.5 | ≥40 |

| LC Connector | ≤0.25 | N/A | ≥40 |

| SC Connector | ≤0.25 | ≤0.5 | ≥50 |

| FC Connector | ≤0.25 | ≤0.5 | ≥50 |

Fiber Optic Connector Market

The business of global fiber optic connectors have achieved big success over the past few years. The global fiber optic connector market is expected to reach USD 5.9 billion by 2025, according to a new report by Grand View Research, Inc. and is expected to gain traction over the forecast period. The global marketplace is majorly driven by the growing adoption of the fiber optic technology. The fiber optic connector market type includes different fiber optic connectors such as SC connector, LC connector, FC connector, ST connector, MTP connector, and others. Based on fiber optic applications, the market is segmented into military & aerospace, oil & gas, telecom, medical, BFSI, railway, and others.

Fiber Optic Connector Installation

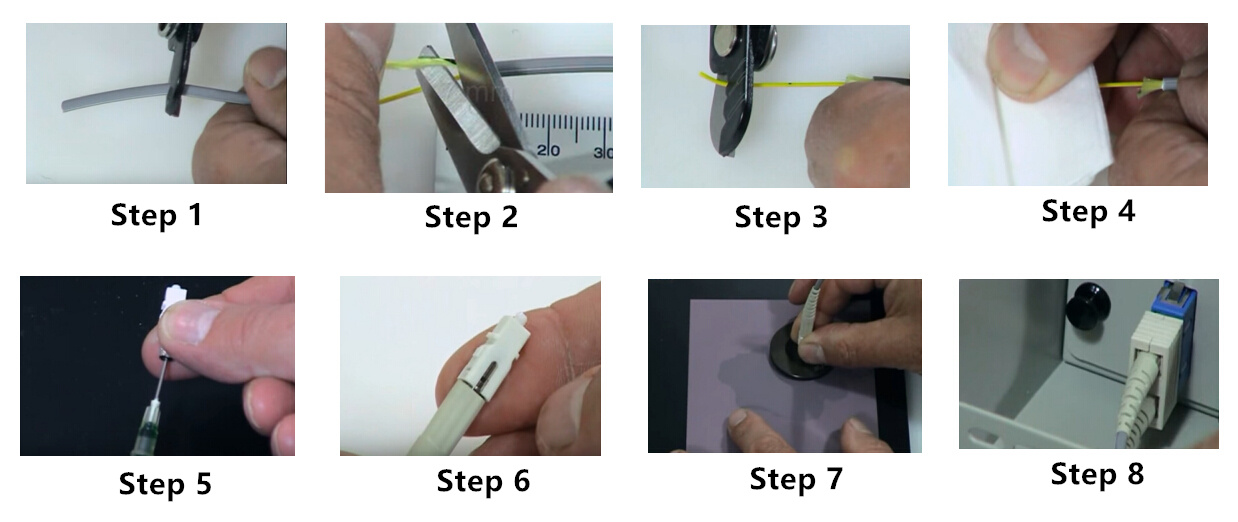

It is easy to install fiber optic connector, a fiber optic cable connection can be completed within 30 minutes. Just follow the following steps:

- Step Ⅰ: Strip the plastic jacket at the end of the fiber optic cable. Optic cable ends have jackets to prevent any damage in shipping from the manufacturer. Clamp the plastic jacket, using a fiber optic stripper tool, which has a designated slot to fit the size of a fiber optic jacket. Squeeze the handles of the stripper like pliers. Pull the jacket away from the fiber optic cable.

- Step Ⅱ:Open the back chamber of the epoxy glue gun by twisting off the back cap. Insert the epoxy glue tube into the chamber and squeeze lightly. You will only need a few ounces of glue for the task. Screw the cap back on the epoxy glue gun chamber.

- Step Ⅲ:Inject epoxy glue into the fiber optic connector socket. Each fiber optic connector has two sockets on each side of it to form the connection. Insert the glue gun into the connector socket. Press and hold the trigger to insert the glue. The glue should spot should not be larger than an eye pupil.

- Step Ⅳ:Insert one fiber optic cable end into the connector sockets. Hold the cable in the socket and count to 10. Let go of the fiber optic cable and connector. Check that the cable stays in position once you let go of it.

- Step Ⅴ:Place the new fiber optic connection into an an epoxy curing oven. Turn on the oven and turn the timer knob to six minutes. Insert the fiber optic connector attached to the cable into one of the curing oven slots. Press the start button on the oven. Pull out the connector from the oven slot. Wiggle the connector end to test the stability of the connection. If it seems fragile, reinsert the connector into the oven and cook it for a few more minutes. Repeat steps three to five to seal the fiber optic connector on both sides.

Conclusion

This article mainly discussed about the fiber optic connector type, fiber optic connector market, as well as its installation. With the wide variety of fiber optic connectors available today, companies can easily convert to fiber optic networks and start enjoying the benefits of a faster, more efficient work environment. If you need fiber optic connectors, FS.COM is a wise choice. They provide a full range of fiber optic connectors and offer customdized service. The fiber optic connect market ahead will be more beoyant, we shall see.