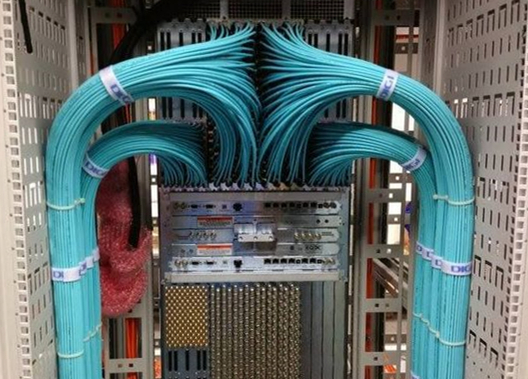

A server rack is an equipment that holds all kinds of network devices ranging from switches, patch panel racks, to cable organizer and so on. Generally, the very first step in rack cable management is to get a container like 42U server rack to support all your devices. However, as there are so many server rack sizes on the market, how to get the one that is ideal for your application needs to be well thought of. Here we can offer some way out.

Common Server Rack Sizes

Based on different application requirements, different server rack sizes are produced. The three common types of server racks are open frame rack, rack enclosure and wall-mount rack.

Server Rack Sizes: Rack Enclosure

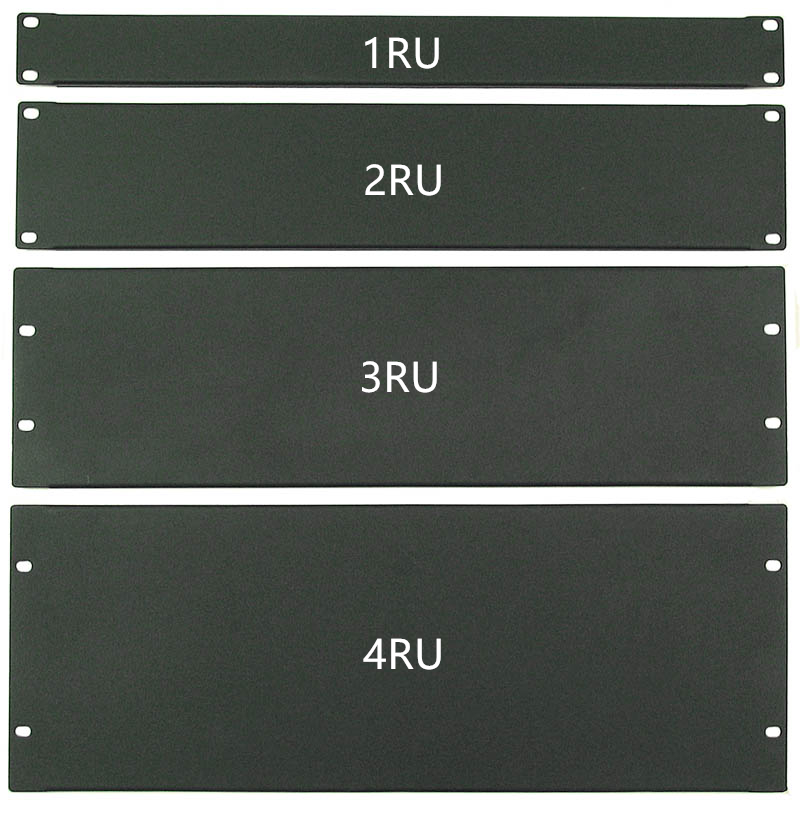

The rack enclosure, also known as server rack cabinet, usually comes in 40U,42U or 45U. It contains removable doors at both front and rear sides, removable side panels and adjustable vertical inside mounting rails, which provides an easy way to install and take out devices. The specially designed perforated door allows for smooth ventilation. Server rack cabinet may come in different height and depth. The height is usually represented by “U” and one U space equals to 1.75 inches. Whereas the depth refers to the distance between the front of the rack and the rear. FS.COM offers 9U server rack, 12U server rack, 42U server rack and 45U server rack. There may be server racks with 48u rack height on the market, which can accommodate as many as 24 2U devices.

Server Rack Sizes: Open Frame Rack

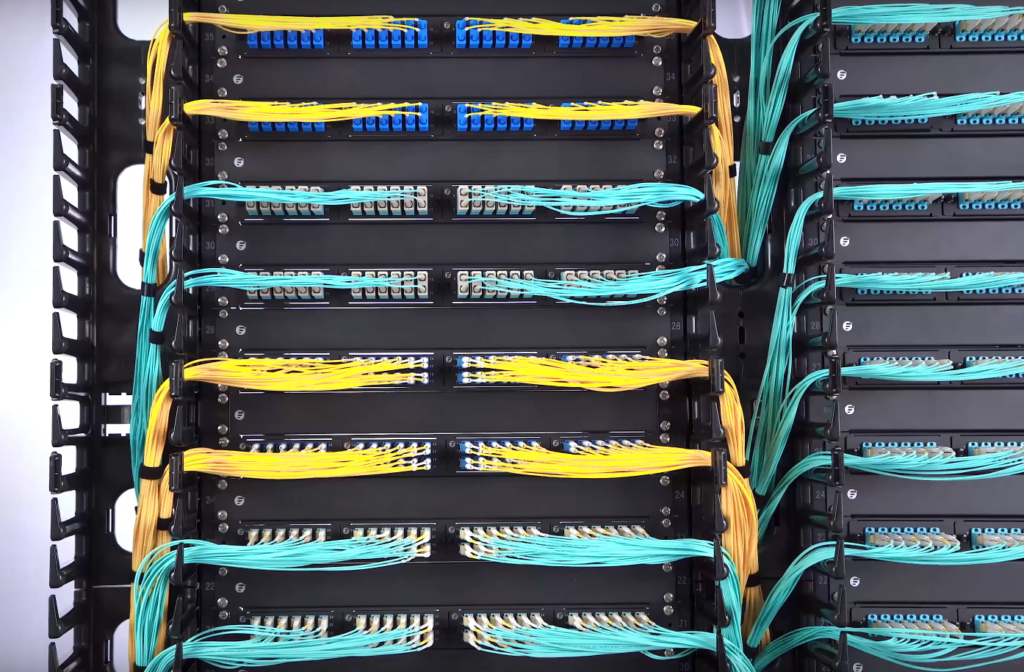

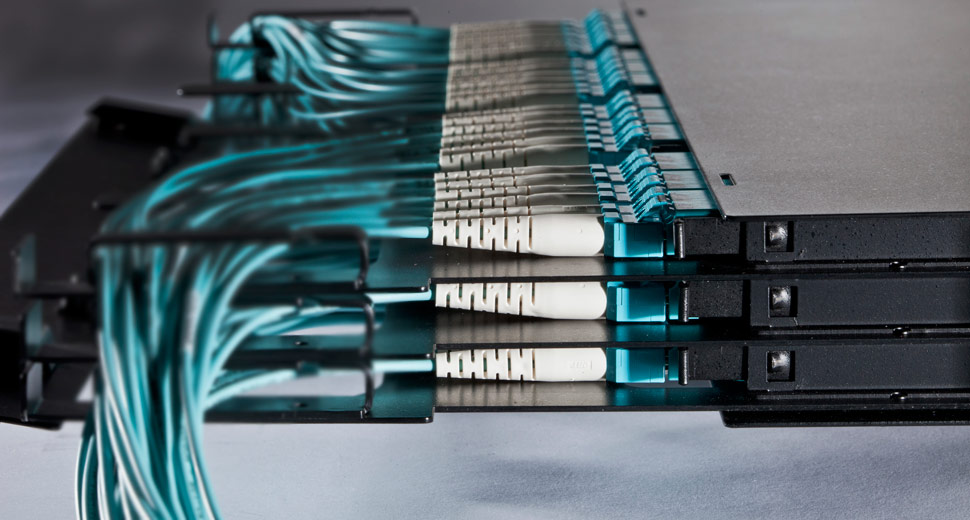

Open frame rack resembles rack enclosure in shape, but it is designed without doors or side panels. Just two or four bare rails are largely economical and leave easy access to cabling. And its common rack size is 45U. Ventilation is no longer a headache for expertise. However, it may expose all your applications to the external environment, resulting in bad appearance or even damage. Given this, open frame racks are optimal for network wiring closet and distribution frame applications that have high-density cabling.

Server Rack Sizes: Wall-mount Rack

Wall-mount rack, the relatively small server rack fixed on the wall, is like a miniature rack enclosure. Usually, the wall-mount server rack sizes are 6U, 9U, 12U and 18U. As it doesn’t occupy the floor space as the former two, the wall-mount cabinet is spacing-saving which can be its selling point. It is suitable for your household use which does not include large and complicated equipment.

How to Choose from These Server Rack Sizes?

If you are not restricted by the space, you can choose from the rack enclosure and open frame server rack. Just calculate the required height and depth of your applications. For example, assume that you need to add 5 2U rack servers to your data center. A 12U server cabinet(21 inches) would be ideal, because 2 x 1.75 x 5 = 17.5 inches of space. The same is to the depth. Remember leaving some cabinet space for both the front and rear for future expansion and current rack cable management. Otherwise, a wall mount server rack is recommended as it is space-saving when you don’t have enough room for floor-standing cabinet. Check out the maximum weight it can hold.

Conclusion

Since the server rack is not flexible or scalable, we must plan carefully for the server rack sizes, and take into consideration the dimension and shape of server racks. As for the quality, rest assured that FS.COM offers sturdy cabinets with reasonable price. We are ready to provide you with the best solution.

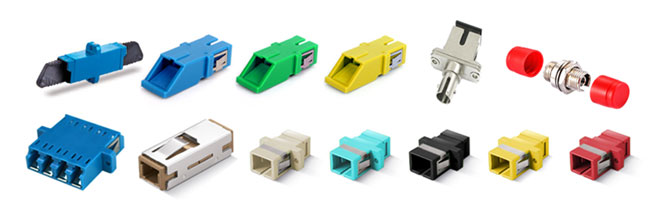

Related article: Wall Mount vs Rack Mount Patch Panel