The dramatic growth of bandwidth requirements in data centers has led to the worldwide use of higher-performance optical products for network scalability, management, flexibility and reliability. Currently, 10GbE (Gigabit Ethernet) can’t meet the increasing needs of high speed transmission well for such applications as Big Data, cloud and Internet of Things being introduced in many industries. As such, network migration to 40G Ethernet has already been the industry consensus.

But as the cost for 100G is far beyond what most enterprises can afford and the technology for 100G is still not mature enough, 40G Ethernet has been a better solution for its lower cost and maturer technologies compared to 100G. Nowadays, some manufacturers are battling for the 40G Ethernet market, which drives down the 40G Ethernet deployment price, leading to the even wider deployment of 40G Ethernet infrastructure. When migrating from 10G to 40G, three aspects should be considered: fiber optic transceiver, transmission media, and pre-terminated MPO assemblies.

For any telecommunication network, fiber optic interconnection is of great importance. Photoelectric conversion is a necessary part in fiber optic network. The function of fiber optic transceiver is photoelectric conversion, which makes it one of the most commonly used components in the data center.

As for 40G transceivers, two different package forms are available: QSFP+ (Quad Small Form-factor Pluggable Plus) and CFP (C Form-factor Pluggable), with the former more widely-used than the latter. A single 40G fiber optic transceiver may not be expensive. But what a medium-sized data center needs is thousands of optical transceivers, meaning a large sum of money to be spent. In such a case, third party transceivers that are compatible with a variety types of switches come into point. They have the same performances that the original brand transceivers have, but cost less money. When selecting 40G compatible transceivers, cost and quality are very important. Choosing the compatible 40G transceivers from Fiberstore can ensure 100% compatibility and interoperability. The picture below shows the testing of Cisco compatible QSFP-40G-SR4 transceivers on a Cisco switch to ensure its compatibility and interoperability.

Allowing for several situations that may exist, the IEEE 802.3ba specified the different transmission media for 40G links, including the following listed media:

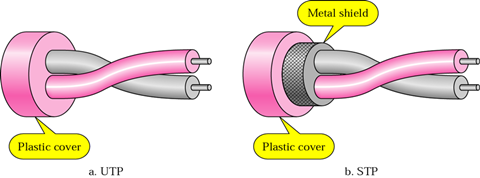

- 40GBASE-CR4: 40Gb/s Ethernet over copper cable in short transmission distance.

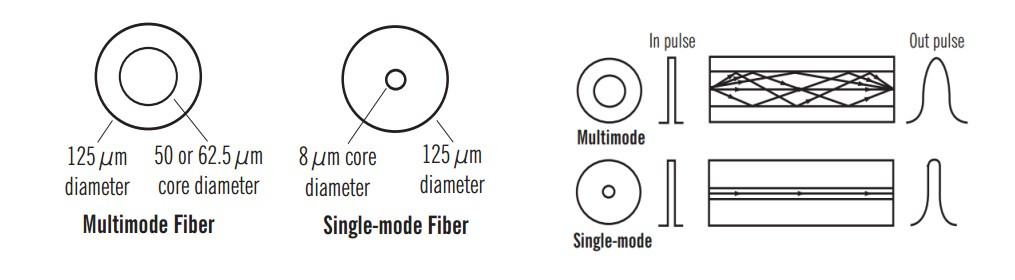

- 40GBASE-SR4 (eg. QFX-QSFP-40G-SR4): 40Gb/s Ethernet over four short-range multi-mode fiber (MMF) optic cables.

- 40GBASE-LR4: 40Gb/s Ethernet over four wavelengths carried by a signal long-distance single-mode fiber (SMF) optic cable.

There also exists hybrid cabling solutions for 40G applications, like QSFP to 4SFP+ breakout cabling assembly. Take QSFP-4SFP10G-CU5M for example, this product listed in Fiberstore is the QSFP+ to 4 10GBASE-CU SFP+ passive direct-attach copper transceiver assembly with 5-meter reach.

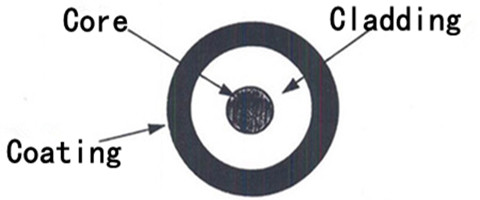

Question occurs: fiber optic cable or copper cable, which should be used in 40G migration? Copper is cheaper. But it can only support 40G transmission limited to several meters. SMF supports the longest 40G transmission distance up to 40 km. As for MMF, OM3 and OM4 are suggested to support short distance transmission. The longest distance that OM3 can support for 40G transmission is 100 m. OM4 can support a longest 40G transmission distance of 150 m. The selection of transmission media should depend on the specific applications.

The IEEE 802.3ba standard also specifies multi-fiber push-on (MPO) connectors for standard-length MMF connectivity. Most of the 40G multi-mode Ethernet transceivers are based on the MPO technology. It is wise to increase fiber optic density by using MPO technology, but a new problem arises. As the fiber number increased, the cabling and splicing difficulty in data center increased. Unlike traditional two-strand fiber connections, MPO connectors cannot be field terminated easily. Thus, most of the data centers choose the pre-terminated MPO assemblies in 40G deployment, which is more reliable and can save more human labor. Before cabling, determine the cabling lengths and customized pre-terminated MPO assemblies with manufacturers would save a lot of time and money.

Using compatible third party transceivers of high quality for 40G Ethernet links saves a lot of money. Taking specific applications and characteristics of 40G transmission media into consideration can also help you to save cost. Pre-terminated MPO assemblies are necessary for flexible and manageable cabling in 40G deployment. With these information in mind, cost-effective 40G Ethernet migration is at the corner.

as well as improved troubleshooting and reconfiguration during moves, adds and changes. Except for that, it has other advantages reflected in these sides:

as well as improved troubleshooting and reconfiguration during moves, adds and changes. Except for that, it has other advantages reflected in these sides:

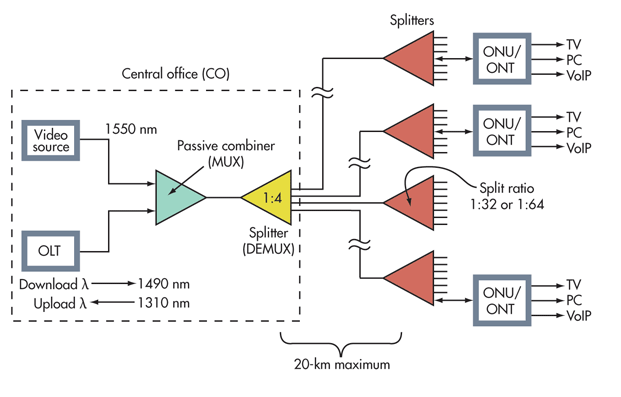

OLT: The optical line terminal is the main element of the network and it is usually placed in the Local Exchange and it’s the engine that drives FTTH system. OLT has two float directions: one is upstream getting distributing different type of data and voice traffic from users, the other is downstream getting data, voice and video traffic from metro network or from a long-haul networkand sending it to all ONT modules on the optical distribution network (ODN). The picture on the left shows an OLT.

OLT: The optical line terminal is the main element of the network and it is usually placed in the Local Exchange and it’s the engine that drives FTTH system. OLT has two float directions: one is upstream getting distributing different type of data and voice traffic from users, the other is downstream getting data, voice and video traffic from metro network or from a long-haul networkand sending it to all ONT modules on the optical distribution network (ODN). The picture on the left shows an OLT. ONU/ONT: Optical network terminals or units are deployed at customer’s premises. ONTs are connected to the OLT by means of optical fiber and no active elements are present in the link. A single ONT can serve as point of access for one or multiple customers and be deployed either at customer’s premises or on the street in a cabinet. The ONU usually communicates with an ONT, which may be a separate box that connects the PON to TV sets, telephones, computers, or a wireless router. The ONU or ONT can be the same device. The picture on the right shows an ONT.

ONU/ONT: Optical network terminals or units are deployed at customer’s premises. ONTs are connected to the OLT by means of optical fiber and no active elements are present in the link. A single ONT can serve as point of access for one or multiple customers and be deployed either at customer’s premises or on the street in a cabinet. The ONU usually communicates with an ONT, which may be a separate box that connects the PON to TV sets, telephones, computers, or a wireless router. The ONU or ONT can be the same device. The picture on the right shows an ONT.