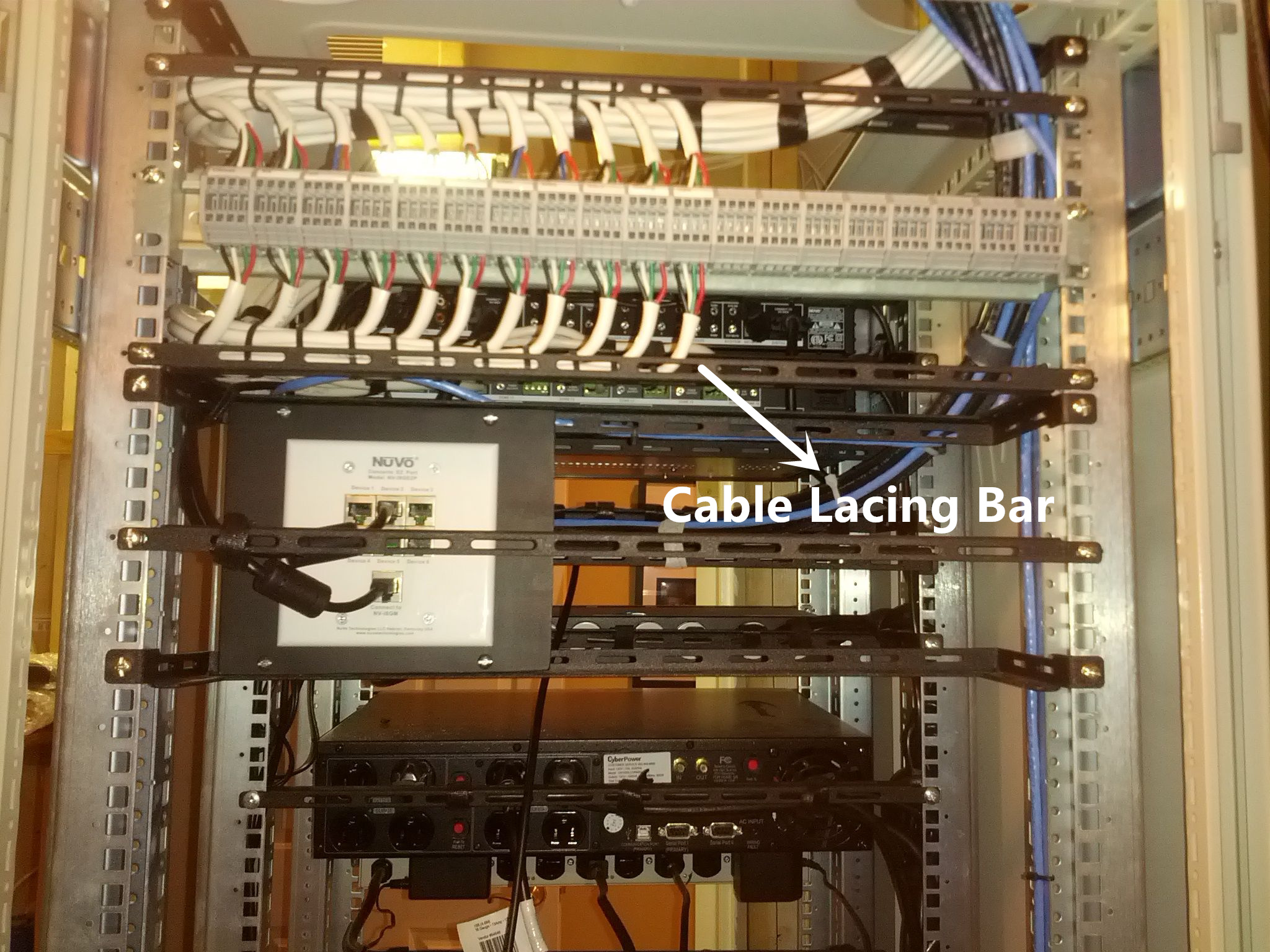

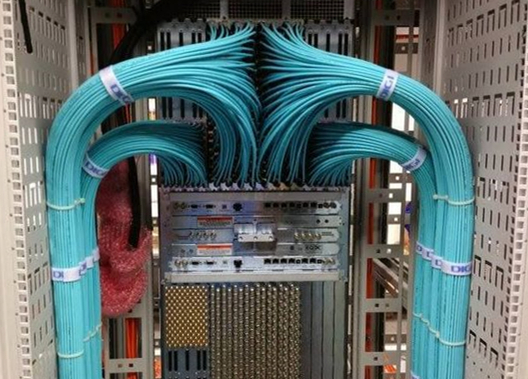

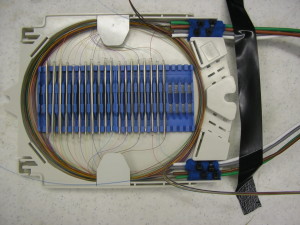

Along with the trend for high density connectivity in server rooms or data centers, cable management has become more difficult than ever before. Cable mess often occurs on the racks causing tremendous problems for later installation and cable maintenance. Network installers are searching for effective tools to make structured cabling. Cable manager appears to be an optimal management accessory. Today, many places adopt this component for cable routing in a simpler way. This article aims to introduce some cost-effective cable manager solutions for you.

With the help of cable manager, cables are perfectly protected from strain to ensure the network reliability. Besides, cable manager also ensures the data integrity in a more organized way. Space is rationally used with a safer cable routing. It is pretty simple to install the cable manager and use it to arrange large amount of cables. The cost of cable manager is always affordable which is a necessary invest to avoid huge loss caused by cable mess in the future.

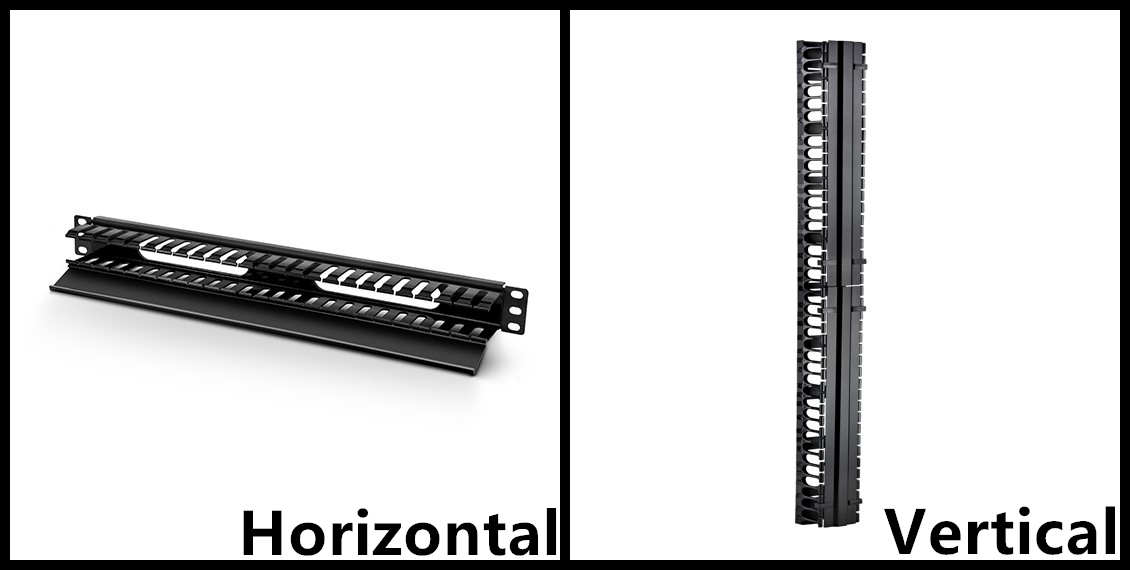

Cable manager can be used for either horizontal direction or vertical direction. The horizontal cable manager allows neat and proper routing of cables from devices in racks. It is important to make sure the rack height and cable density is supported by the cable manager. Typically, 1U and 2U horizontal cable managers are more popular in use. You also need to ensure that the horizontal cable manager is not obstructing devices in racks and cables are free to add or remove. Another solution is vertical manager. It can arrange the slack patch cables in vertical space allowing for 50 percent growth of cables and eliminating the use of horizontal cable managers.

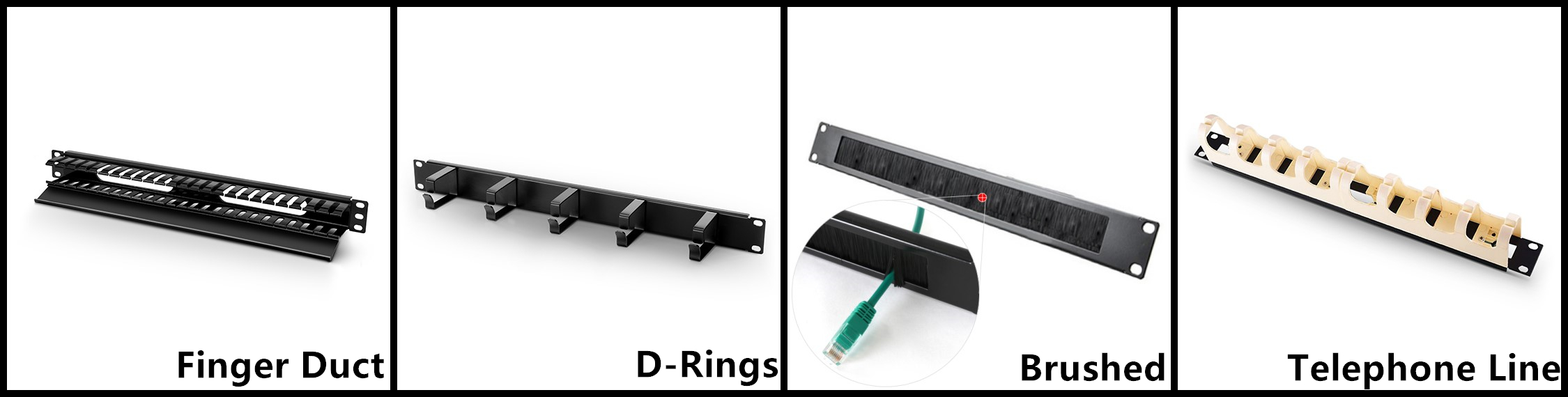

Cable manager usually has various styles. First is the type with finger duct. The flexible finger ducts can maximize the care and protection of the equipment and cables. The holes are easy to pass through for convenient cabling. Second type has the D-rings and is available for horizontal, vertical or diagonal positions in cable management. Third is the cable manager with brush slots. This unique design can protect the cable from most contaminants and effectively increase the air flow at the same time. Last cable manager style is especially used for telephone line. It is often constructed by a base within two 110 cable management blocks.

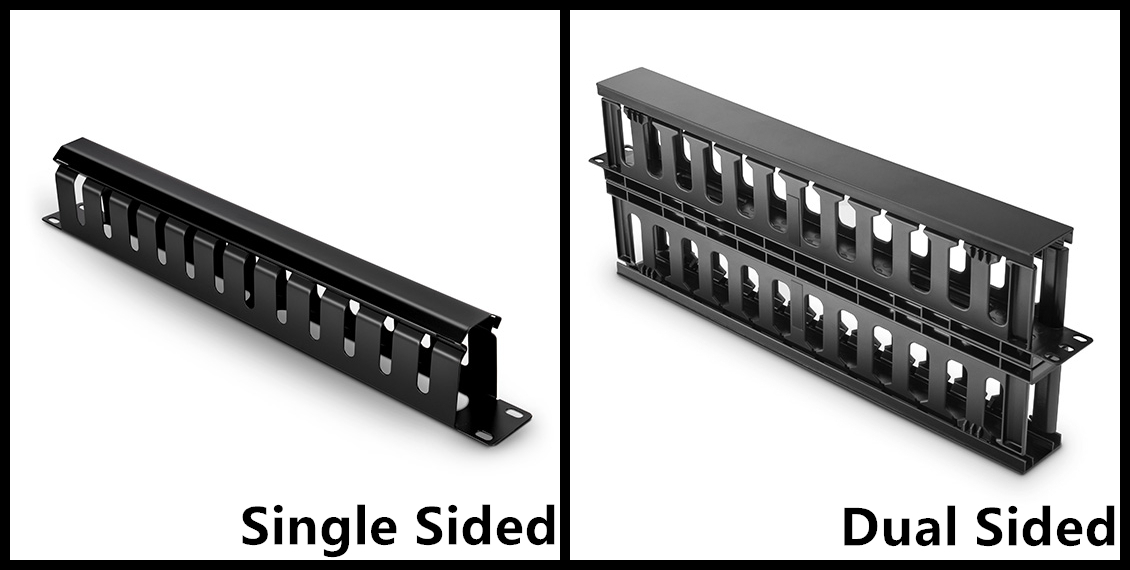

Structures of cable manager can be divided into single sided and dual sided types. Single sided manager provides a convenient cable run between equipment and racks, while dual sided manager supports patch panels by keeping different cables separate for better distinction.

Generally speaking, cable manager can be made of three kinds of materials as plastic, metal and semimetal. Plastic and metal are the most common materials. Plastic cable manager is definitely lighter in weight for easier installation. Metal cable manager is more solid to protect the cables from any damage.

In summary, cable manager is now widely used for cable routing in racks. Having a structured cabling is beneficial to future management of cables. It’s never too late to sort out the cables if you want your network to achieve a higher performance for data transmission. FS.COM provides all kinds of cable managers mentioned above. If you are interested, please visit www.fs.com for more information.