Fiber optic connectors are used to the mechanical and optical means for cross connecting fibers. Fiber optic connectors can also be used to join fiber cables to transmitters or receivers. There have been many types of connectors developed for fiber cable. Single mode networks have used FC or SC connectors in about the same proportion as ST and SC in multimode installations. But LC connector with smaller size and higher performance has become popular and the connector choice for optical transceivers for systems operating at gigabit speeds. The following text gives a detailed introduction of LC connector.

LC stands for Lucent Connector, as the LC connector was developed by Lucent Technologies as a response to the need by their primary customers, the telcos, for a small, low insertion loss connector. Then the LC design was standardized in EIA/TIA-604-10 and is offered by other manufacturers.

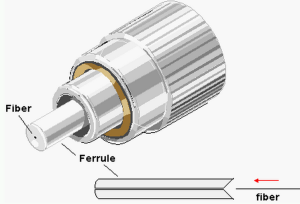

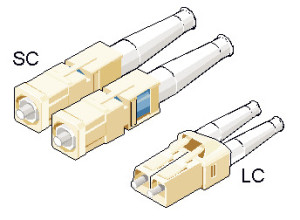

There are solid reasons that the LC is the preferred connector for high-performance network. From the appearance, LC connect is like a mini size of SC connector. LC connector borrows split-sleeve construction and a cylindrical ferrule (usually ceramic) from SC connector. LC connector has a push-and-latch design providing pull-proof stability in system rack mounts. The picture on the right shows the appearance of SC connector and LC connector.

The ferrule size of LC connector is 1.25 mm which is half the size of SC connector ferrule—2.5 mm. LC connector is rated for 500 mating cycles and its typical insertion loss is 0.25 dB. An interesting feature of the LC is that, in some designs, the ferrule can be “tuned” or rotated with a special tool after it has been assembled. This offers a considerable performance advantage. The design and performance of LC connector address the need for high density and low insertion loss.

LC connector can be found in many places for termination and connection, especially SFP transceivers for gigabit transmission. For example, the optic interfaces of Cisco SFP transceivers are all LC connectors. Some other applications are as following:

- Telecommunication networks

- Local area networks

- Data processing networks

- Cable television

- Fiber-to-the-home

- Premises distribution

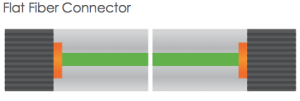

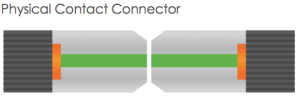

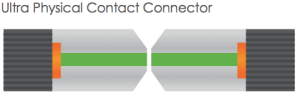

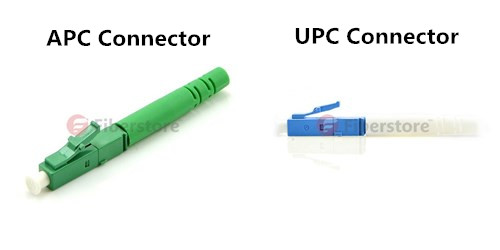

To meet the needs of market, there are various types of LC connectors provided now. During the selection of LC connector, transmission media should be the first factor to consider. LC connector favors single mode fiber optic cable. But it can also be used with multimode fiber optic cable. Signals sometimes are transferred over simplex fiber optic cable and sometime duplex fiber optic cable. Thus, LC connector has both simplex and duplex design. The picture above shows an APC simplex LC connector on the left and a UPC duplex LC connector on the right. Some other factors like polishing style (APC or UPC), hole size and cable diameter should not be ignored. For more details about LC connectors, you can visit Fiberstore which provides various LC connectors with high performance and low price.