Generally speaking, data center is designed to keep the continuous operation of computer servers in an entire building or station. Likewise, server room is also devoted to this purpose but with a much smaller space. If you are only running a small business, then a small server room is enough. But you should not think that a small server room does not need proper building plan. Actually, having a solid design is very necessary to prevent future headaches. Well-organized server room ensures the effectiveness and viability of your business. This article will provide you with some considerations for setting up a small server room.

With the growth of company, equipment may pile up day by day. It is dangerous to expose these equipment randomly to the working environment. A minor accident like coffee spill or stumble can cause great loss. Gladly, using server racks will effectively solve these unnecessary problems. But how to choose the suitable racks? Most importantly, server racks with sufficient inner space is beneficial to future equipment expansion. Today, server racks are usually in free-standing style or wall-mounted style. But you need to remember that no matter which type you choose, following the installation instructions can secure your racks from rack movement which may cause further disruption and damage.

If budget permits, having a separate server room can both effectively reduce the equipment noise and secure the equipment from theft, physical tampering, and accidents. However, small company may have no choice but to place the rack in the corner of the room. Therefore racks with sound-dampening properties are welcome to be set up within such small areas. Completely soundproofing is impossible, but overall sound reduction can be achieved.

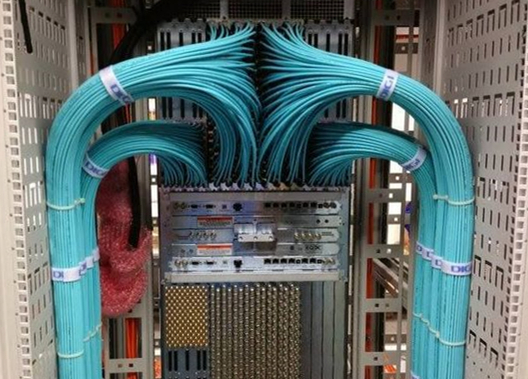

High temperature in your server rack will dramatically shorten equipment lifespan or even lead to crashes or outages. For the safety of the equipment, environment and company, you need cooling strategies to control the heat. Installing air-conditioning units is a good way to keep your equipment cool and lower the surrounding temperature. Also, a structured cabling will contribute to the heat control.

Do not regard cable management as an unnecessary trifle. Sometimes it is the hidden danger in the future. You’d better keep good cable management right from the start. Properly bundling cables together behind equipment allows easier access to servers. When bundling your cables, it’s common practice to bundle by server and then group those bundles together. Related tools such as cable ties can be used to support the management process.

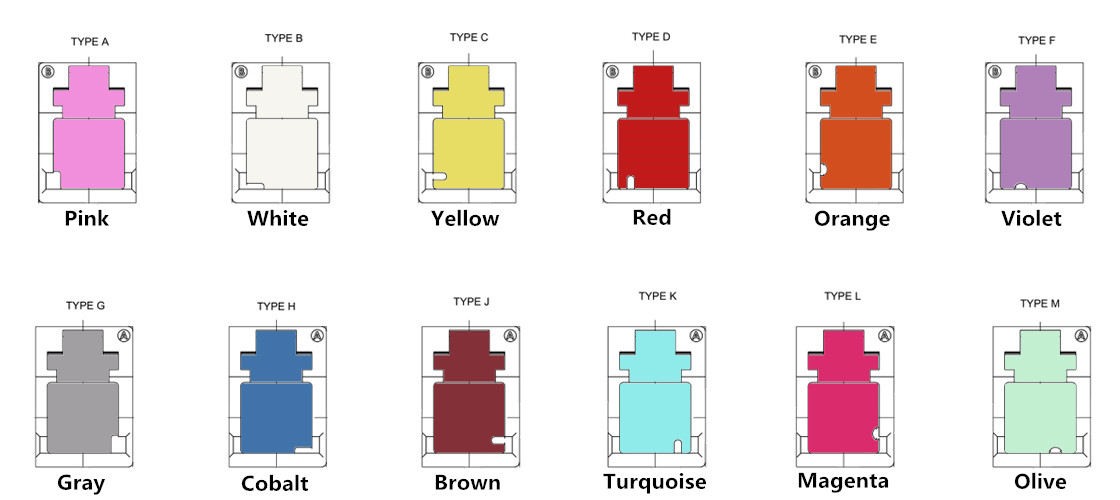

Another tip for managing your sever room in good order is to label all the cables. In this way, you can easily identify the right cable within a short time. Other accidents like systems being unplugged or restarted without warning can also be prohibited. When labeling your cables, you should include the information of where the cable connects to and from and a unique ID identifying the cable. Nowadays, many types of cable ties are available with the marking function.

Server room is an essential part of your company which contains all the important pieces that keep your business operating smoothly. Setting up a nice server room can keep your equipment away from damage and increase the working efficiency. Of course, if you are not professional, consulting a specialist for help is always recommended.