Cabling is not some easy thing. Many problems might come out while cabling. Sometimes the fiber optic cable is not long enough. Sometimes there are too many fiber optic cables that need great efforts to ensure the management of them. The protection and maintenance of the fiber optic cable are also essential. These are just some of the most common problems that people meet during cabling. In this article, two common and useful products will be introduced to help you solve the most common problems while cabling. They are fiber splice tray and wall mount network cabinet.

Fiber Splice Tray

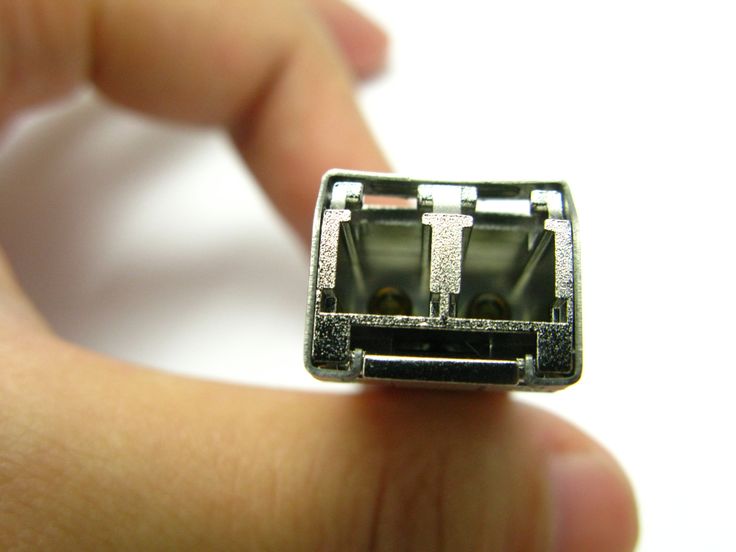

Fiber splice tray is a kind of optical distribution frame. Generally, fiber splice tray is a container used to organize and protect fibers and spliced fibers. It is designed to provide space for the connection of fibers and spliced fibers.

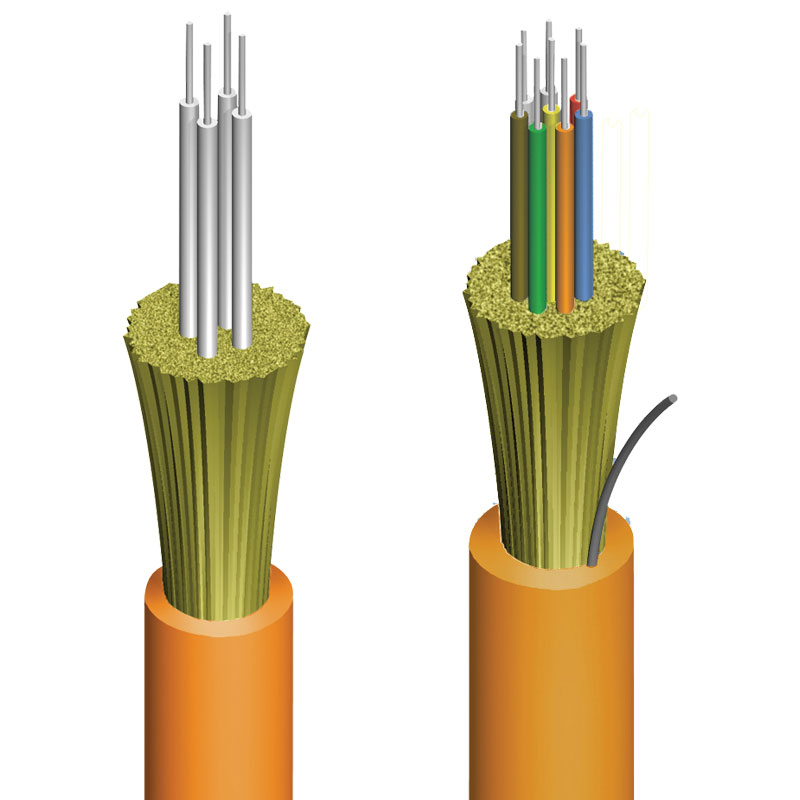

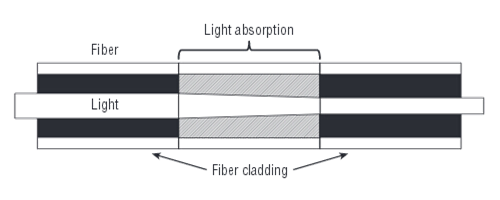

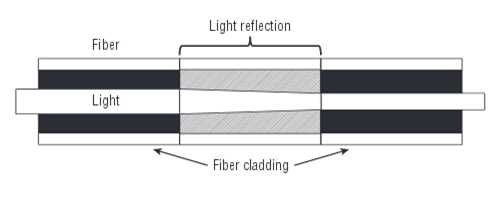

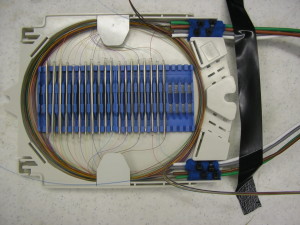

Different fiber optic cables can be melted connected directly via the fiber splice tray. In addition, fiber optic cable can be connected with pigtail via the tray, and via the pigtail it can connect out to their fiber optic equipment. With the help of fiber splice trays, the problem that the fiber optic cable is not long enough can be solved. Fiber splice tray is made of engineering plastics and it features as flame retardant, high strength and aging resistance. Thus it can protect the fiber and spliced fibers very well. In addition, as the fiber splice tray provides space to hold the melted connected fibers and spliced fibers, it can help to manage the fiber optic cables to some degree. This function can be seen from the picture of a splice tray below:

Fiber splice tray is one of the most common components being used during cabling. It can offer various of unique and flexible splice and storage possibilities.

Wall Mount Network Cabinet

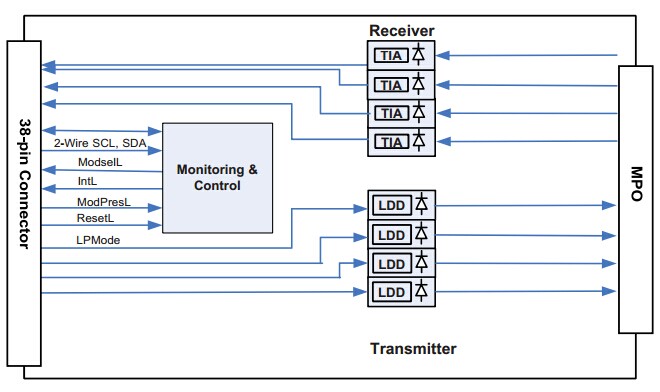

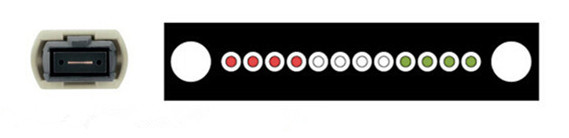

Wall mount network cabinet is one of the most commonly used distribution cabinets. It provides a flexible fiber management system for transitioning outside plant cable to inside cable and connector assemblies and can be installed on the wall.

Wall mount network cabinet has great advantages in fiber optic cable management and protection. The wall mount network cabinet is usually layered structure, which helps a lot while organizing equipment and cabling in limited space. Moreover, the maintenance of fiber optic cables connected with wall mount network cabinet is very convenient and efficient. The cabinet generally contains power supply and fan, which can help the fiber optic cables work well and work longer. Various sizes and types of wall mount network cabinets are provided. Factories install different adapters in the cabinet to satisfy the needs of the markets. Costum-made cabinet is also very popular.

With the help of wall mount network cabinets, cabling work will be much more easier and systematic. The cabinet provides a safe place for the fiber optic cables connection in limited space. It is now widely used in the cabling of various areas.

The choice of appropriate components during cabling does not only simplify the work, but also helps a lot in cost saving, space savings, products operation and maintenance. Fiberstore Inc. designs, manufactures and sells a comprehensive line of high performance, highly reliable fiber optic communication systems and modules for metropolitan area, local area and storage area networks. Fiberstore can provide different sizes of wall mount network cabinets and various types of fiber splice trays which can contain 4 fibers, 6 fibers, 12 fibers, 16 fibers, 24 fibers, 32 fibers and so on.