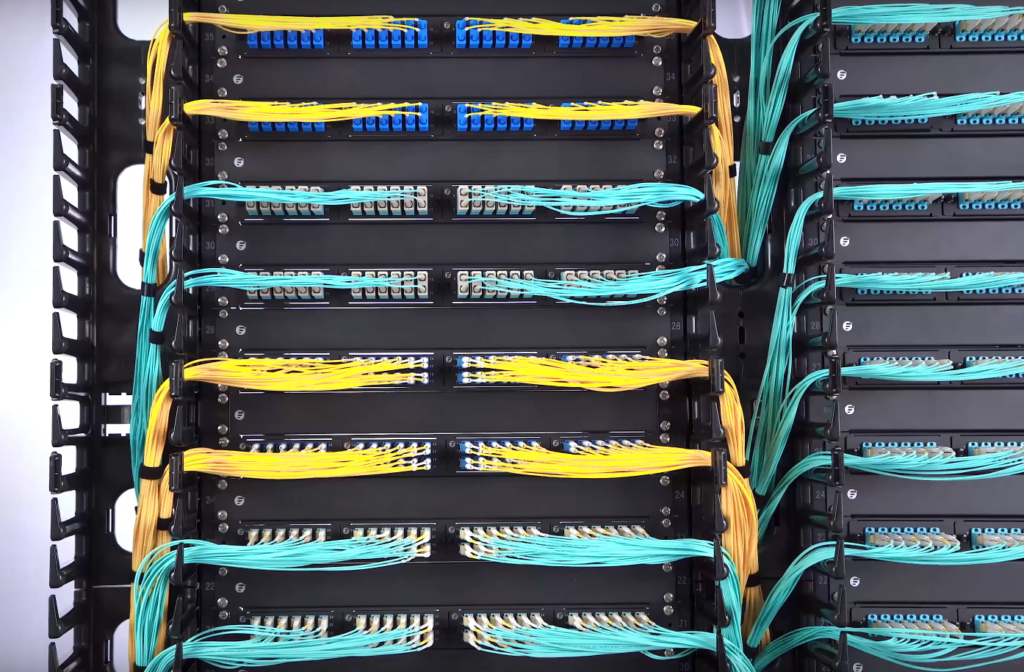

Cable management, especially rack cable management, is a always the time-consuming and tedious job for IT network workers. Cable organizers like patch panel, 1U/2U cable managers and D-rings are commonly used by network workers in server rack cable management. Then how to use these cable organizers for rack cable management effectively? This article will explore some details for you.

Single-sided Cable Organizer in Rack Cable Management

The single-sided vertical cable organizers, also known as cable manager, are usually installed on open frame racks to organize and protect cables. As it is single-sided, the finger ducts are facing towards the front side or users. It is in most cases attached to the rack and won’t take up much room in rack cable management. The 45U single-sided cable organizer provided by FS.COM is capable of managing all the fiber and copper cables in a server rack. It is equipped with molded cable management fingers which have integral bend radius control. Each of this single-sided vertical cable manager consists of two 22.5U sections in one package. The two parts can be seamlessly combined together when they are installed along a standard 45U height server rack. The user-friendly cover on this rack cable organizer can help protect the cable from damage and dust-proof, and also hide the cables inside.

Dual-sided Cable Organizer in Rack Cable Management

Different from the single-sided cable organizer, the dual-sided cable manager is designed with management fingers on both front and rear sides. The double-sided structure enables the maximize space utilization, which can better meet the vertical cable management need. The 45U plastic dual-sided vertical cable organizer is deployed to deal with the slack cables, preventing the chaotic cable runs. Its soft finger ducts on front and back sides allowing for quick and easy cable routing on the server racks. Two 22.5U sections being coupled seamlessly form a complete 45U dual-sided vertical cable manager which is suitable for both fiber and copper cabling. The covers on both sides can protect cables from damage and dust. It can be a good partner of horizontal cable managers. In addition, this vertical cable manager has multiple finger ducts that can store a large number of cables.

How to Use Vertical Cable Organizers for Server Racks

The vertical cable organizers are often deployed where cables run chaotically. When applying them, assemble all the gadgets including the cover and the easily inserted brackets. Use screws to fix them on the open frame rack. After the two 22.5U dual-sided cable organizers being matched seamlessly, the cable management can go on. To produce a tidy and clean appearance, care should be given that the cables on the same row should be passed through the same gaps between two fingers. Get some cable ties to achieve better effects. After the cabling, close the cover. Success. Here is a video introducing how to apply vertical cable organizers in rack cable management.

Conclusion

Vertical cable organizer, or vertical cable manager, can simplify rack cable management effectively. It has nothing to do with the network but serves the cable management. In the cabling system, only combing the cable runs clearly can the network system work in an orderly way. FS.COM has been all along working on the growing conundrum to offer you market-leading quality and novel design. We now have different cable organizers available for your reference to deal with vertical and horizontal cable management.

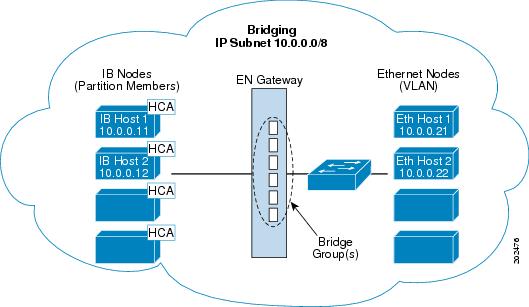

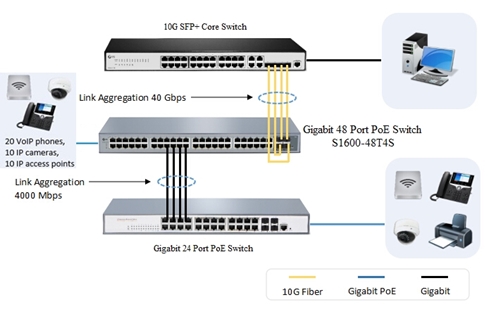

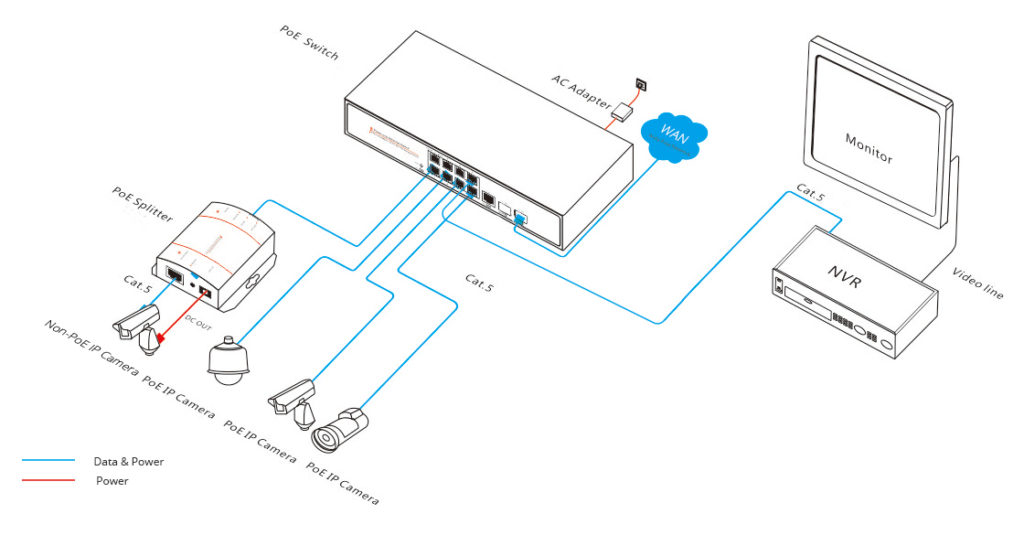

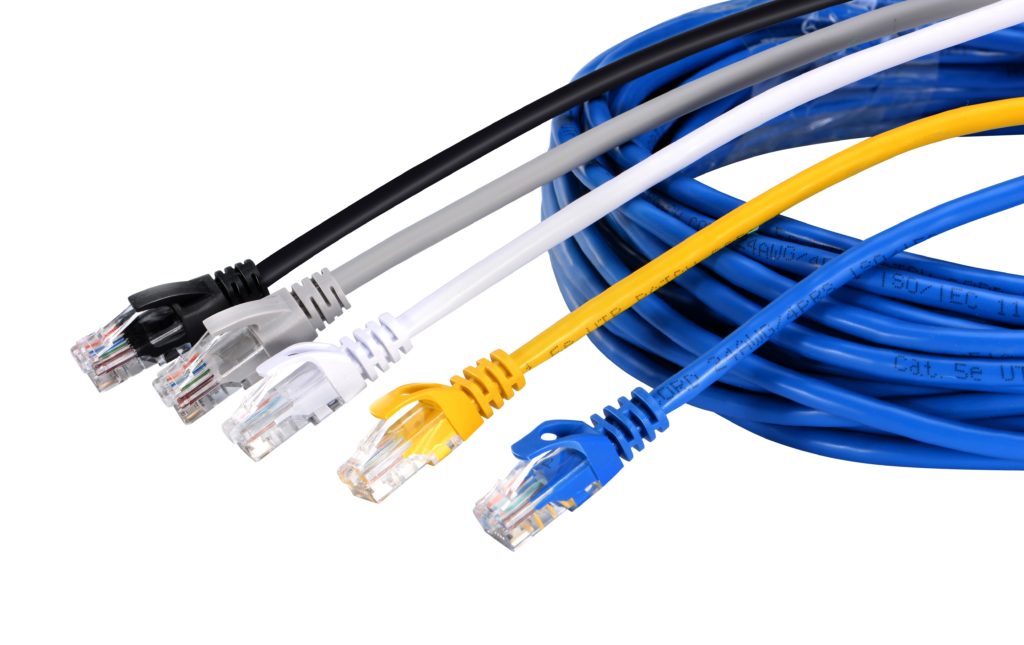

This figure is a display of power cord application.

This figure is a display of power cord application.