When it comes to fiber optic cables, you might be curious about the description that contains UPC or APC. For example, what is LC UPC to LC UPC? And what is SC APC to SC APC? UPC and APC are actually two polish types of fiber ferrules. This article will help you explore the world of UPC and APC to know which one is the better solution for your network.

Return loss is inevitable when installing a connector on the end of fiber. It is a back reflection generated by the light source. However, severe light loss will damage the laser light sources and disrupt transmitted signals. Therefore, different polish connector ferrules are made to avoid serious return loss. UPC and APC are two widely used polish types. Here are some specific information about UPC and APC.

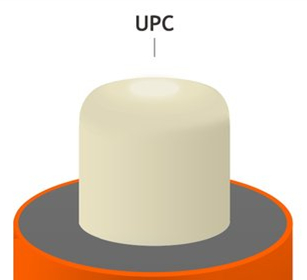

UPC, namely ultra physical contact, is evolved from PC with a better surface finish. UPC connector relies on machine polishing to deliver its low optical return loss characteristics. Its rounded finish created during the polishing process allows fibers to touch on a high point near the fiber core where light travels. In addition, when using the UPC connector, make sure your laser’s specifications can handle the return loss your UPC connector will generate.

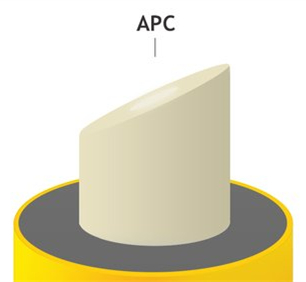

APC, namely angled physical contact, is very different from UPC. The end face of APC connector is precisely polished at an 8-degree angle to the fiber cladding so that most return loss is reflected into the cladding where it cannot interfere with the transmitted signal or damage the laser source. But it is extremely difficult to field terminate an APC connector at 8 degrees with any consistent level of success. Therefore, if an APC connector is damaged in the field, it should be replaced with a factory terminated APC connector.

Many differences can be found between UPC and APC connectors:

Point one, end faces. As we have discussed before, UPC connectors are polished with no angle, but APC connectors is polished at an 8-degree angle.

Point two, ways of light reflection. Their different polish end faces directly lead to their differences in ways of light reflection. Any reflected light is reflected straight back towards the light source if an UPC connector is used. But the APC connector causes reflected light to reflect at an angle into the cladding instead of straight back toward the source.

Point three, return loss. Since their light reflection patterns are varied, their levels of return loss are also different. APC connector offers lower return loss of -65 dB than UPC of -50 dB. As a matter of fact, connectors can achieve better matching performance if return loss is lower.

Point four, connector color. This is the most obvious difference that can be seen from the surface. UPC connector usually has a blue body while APC connector has a green body.

If you are still confused about which polish type to choose, the best way is to see whether their applications complies to yours. In general, the APC type has a better performance than the UPC type. APC is best for high bandwidth applications and long haul links. For example, FTTx (fiber to the x), passive optical network (PON) and wavelength-division multiplexing (WDM) that are more sensitive to return loss, thus APC is a better solution to offer the lowest return loss. However, massive employment of APC connectors will cause higher cost. In this way, UPC might be a better choice because cost budget is of equal importance.

UPC and APC are taken into consideration when choosing fiber optic patch cables. Both of them can reduce light loss and protect laser sources from damage. A wise selection should be based on your actual condition. Hope this article can provide you some help.