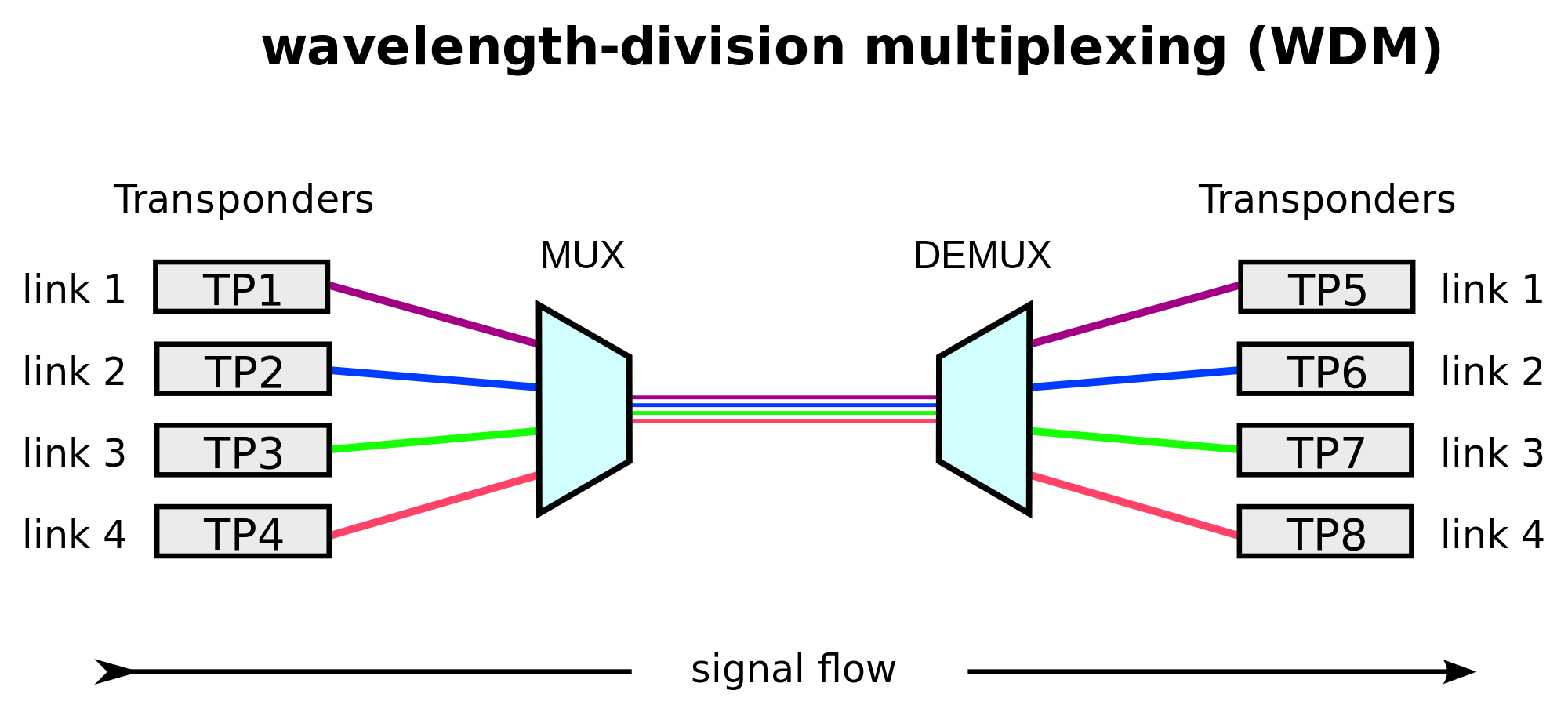

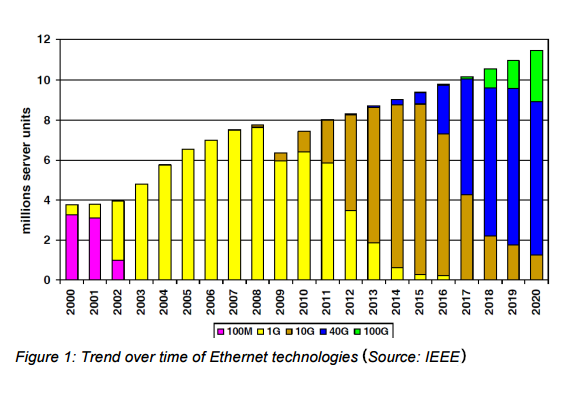

While we are chasing for higher data rates in fiber optic networks, data security is also an important concern for constructing good network environment. Data risks will increase in the expanded fiber optic networks when unauthorized or inadvertent data changes occur. In order to respond to the urgent demand, physically discrete fiber connection systems have emerged for security in high-performance fiber networks. Generally, we call it the keyed LC system. Data risks can be largely reduced at the early stage of the infrastructure design by using a new cabling solution of “keyed” characteristic. This article will take you to explore the world of keyed LC system.

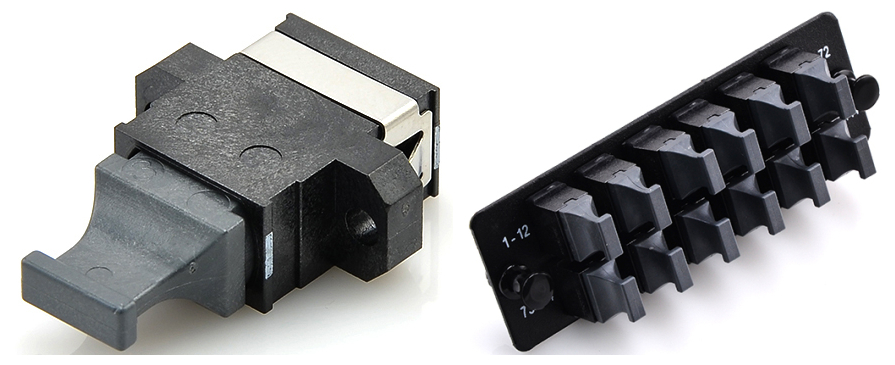

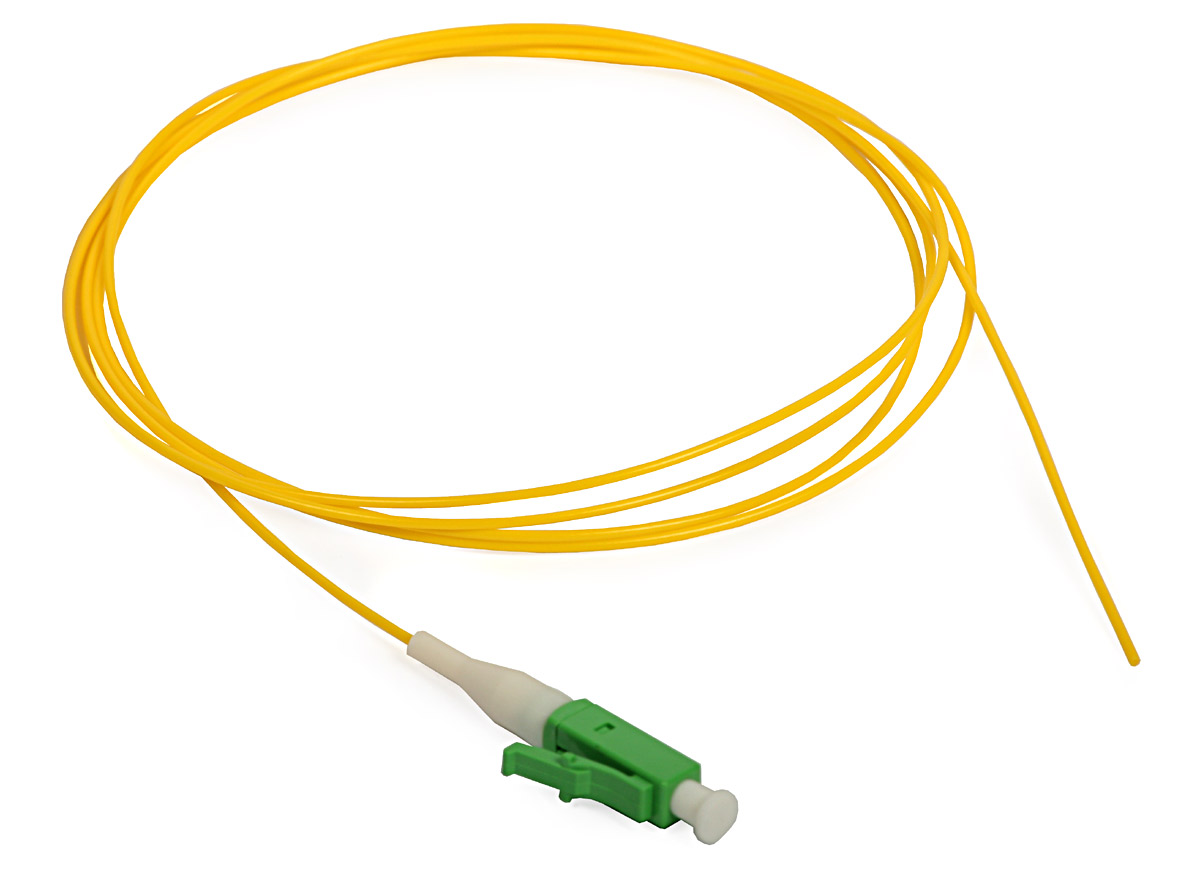

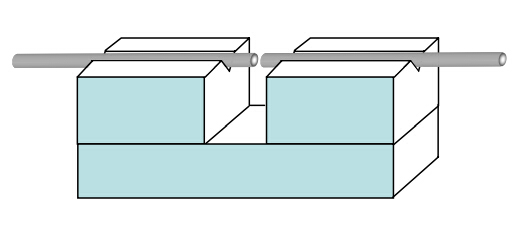

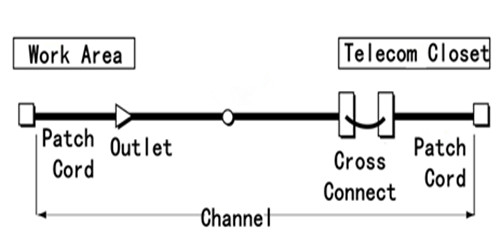

Keyed LC system or secure LC system is a small form factor (SFF) connection system that allows for physical segregation of network segments in secure fiber cabling infrastructure. Different colors are used in the system to identify different network circuits and protect them from accidental moves, adds, or changes. There are 8 or even 12 keying options for keyed LC components, thus 8 or 12 different colors are employed to correspond to the specific option. For instance, this picture shows the typical simplex keyed LC connectivity which only allows yellow colored interfaces to fit in with each other.

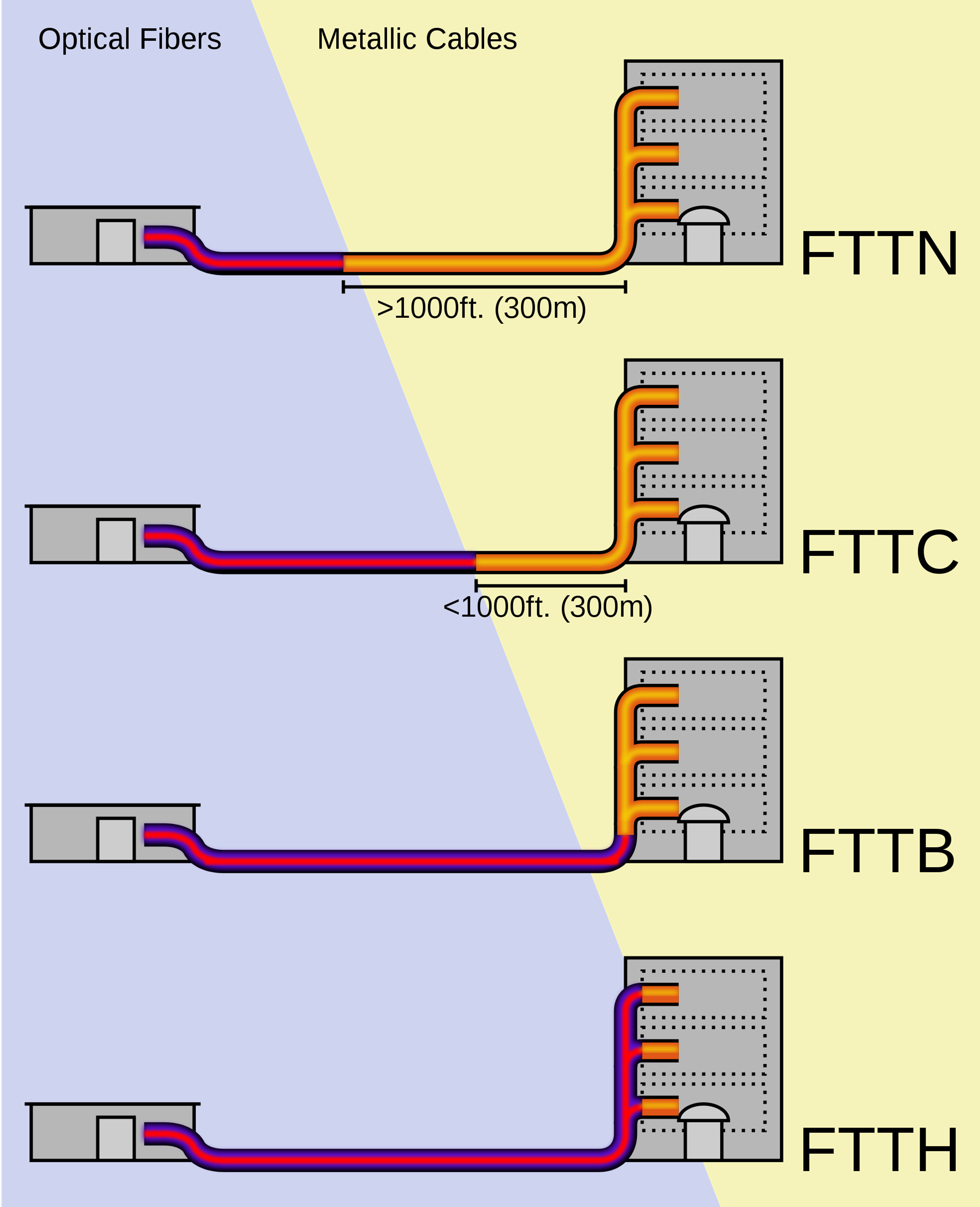

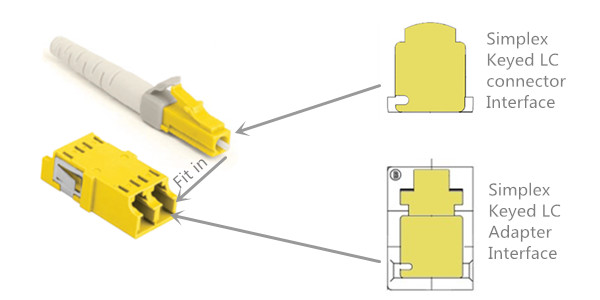

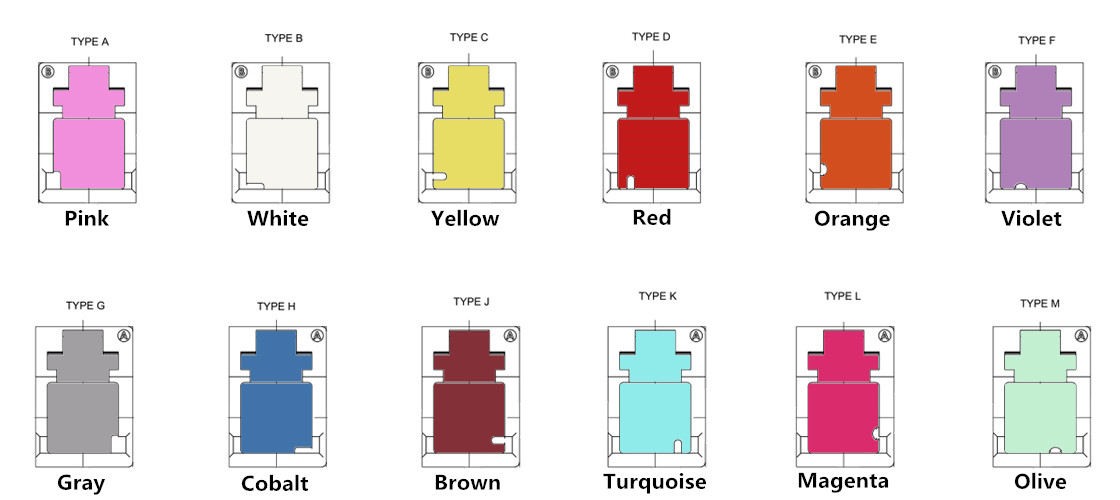

The following picture presents the 12 color coded patterns. Once the color does not match, the keying feature will prevent the connector from carrying the signal.

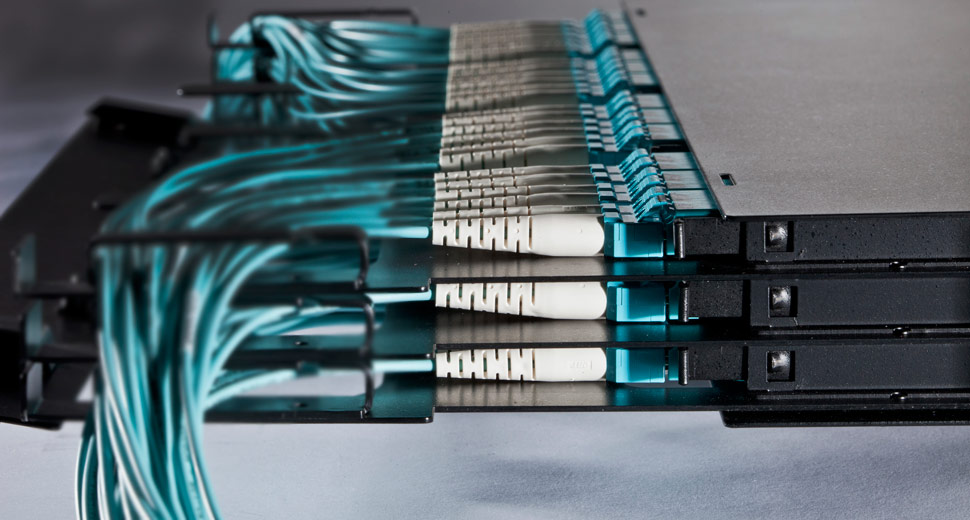

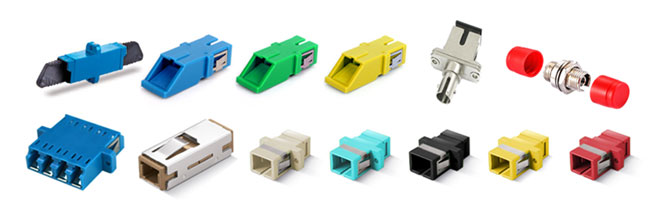

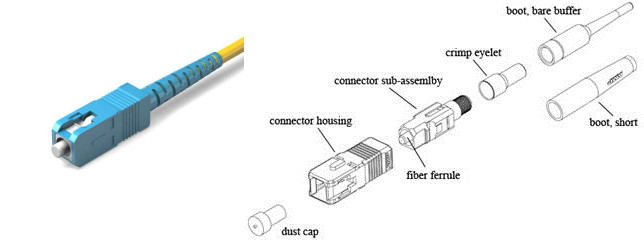

Keyed LC system is a big family that contains various components. Most common members are keyed LC fiber optic connectors, keyed LC fiber patch cords, keyed LC fiber optic adapters, keyed LC fiber adapter panels and keyed LC fiber optic cassettes.

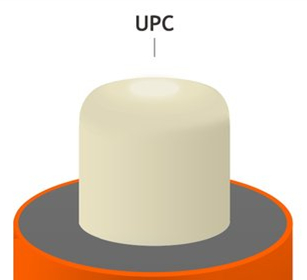

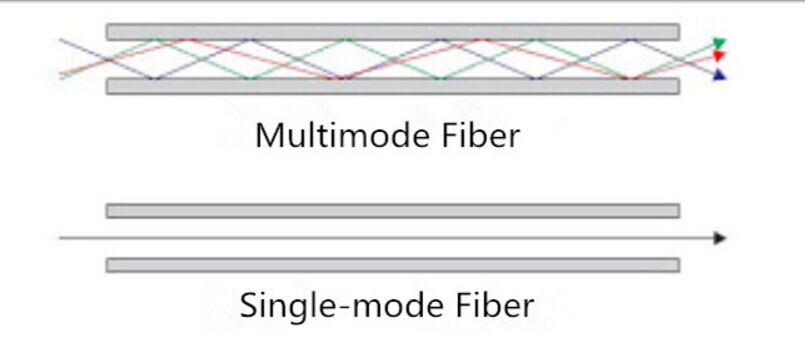

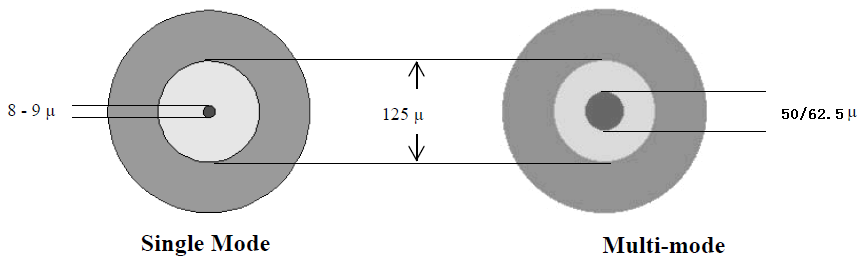

Keyed LC connectors are varied in different colors. When connectors are linked to fiber cables, they combine to be the diverse keyed LC patch cables. These components are used in interconnecting or cross-connecting fiber networks within a structured cabling system. Keyed LC fiber patch cables in single-mode 9/125 um, multimode 62.5/125 um, 50/125 um and laser-optimized 50/125 um are frequently used in the network.

The front and back of keyed LC fiber optic adapters are both keyed to prevent installation errors and possible security breach. They have different color coded keyed patterns for identification and are available for both single-mode and multimode applications.

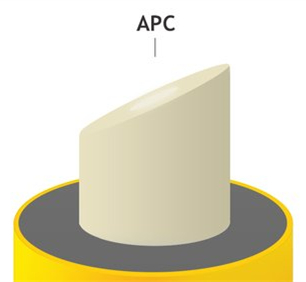

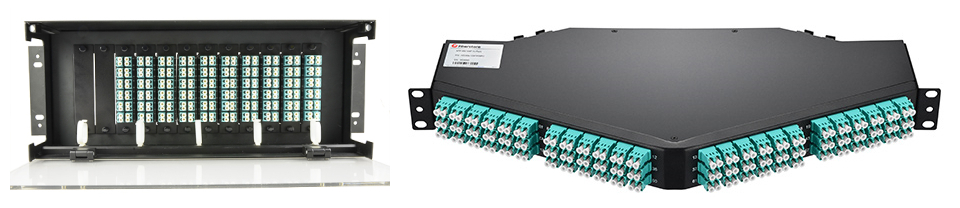

Keyed LC fiber adapter panels with 12, 16 and 24 fibers are available in the market. They are a widely recognized modular solution for restricted fiber cross-connect systems. In data center, equipment room and telecommunications room, keyed LC fiber adapter panels are now frequently used to improve data security levels.

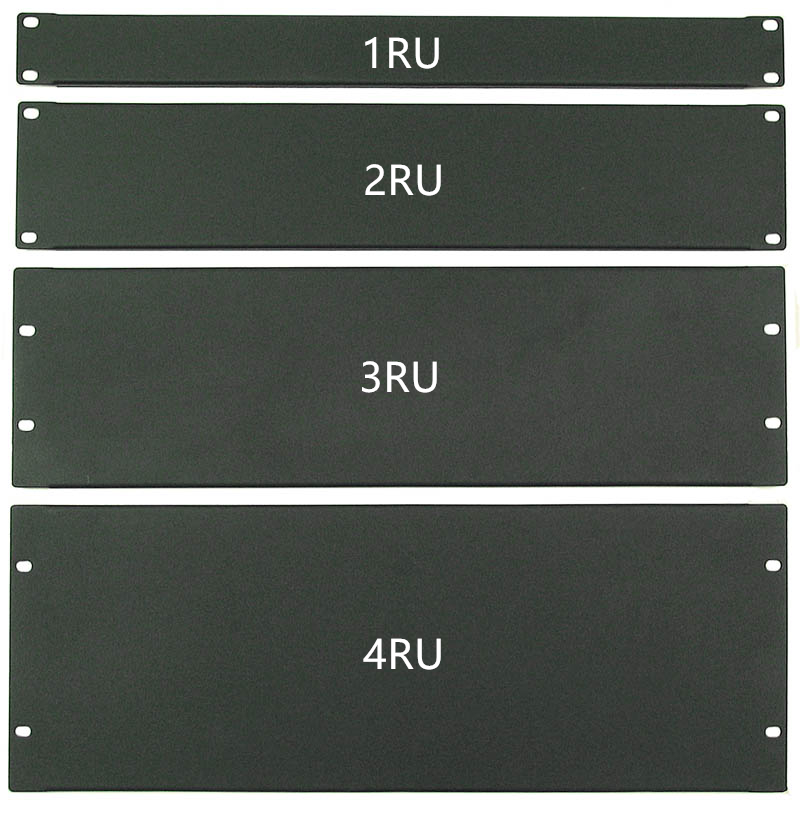

Keyed LC cassettes are widely applied to prevent unauthorized and inadvertent changes in the highly sensitive data center and IT network.

- Point one — data security. It is the fundamental advantage of using keyed LC products. Data transmission is secured by multiple keying patterns. Networks can effectively be limited to certain groups, access levels or customers in a co-location environment, which provides an increased level of security and stability by protecting against incorrect patching of circuits.

- Point two — easy identification. Color-coded keyed LC products are easy to be identified during cable installation and maintenance which saves lots of time.

- Point three — higher performance.Keyed LC products are usually pre-terminated, which cause low insertion loss and greatly increase the fiber optic network performance.

- Point four — flexibility. Two keyed simplex LC connectors can be easily assembled into a duplex LC connector. The polarity of a patch cord can also be reversed easily.

In conclusion, secure/keyed LC system is a modular connectivity system designed to secure fiber networks for higher performance. Great reliability can be achieved and installation becomes more efficient in all areas of a fiber cabling infrastructure.