Fiber patch panel, namely fiber enclosure, is employed for better cable management and cable protection in data centers. With the help of fiber patch panels, it is more time-saving and easier for technicians to do the cabling work. Fiber patch panel terminates the fiber optic cables and provides access to the cables’ individual fibers for cross connection. In today’s market, there are various types of fiber patch panels. Choosing the right one for your network may seem a little complicated. This article will give several aspects that are important for selecting fiber patch panels.

Loaded patch panel is pre-installed with adapter panels or cassettes while unloaded patch panel is empty with nothing inside. Typically, LC and MTP connectors are widely used in loaded patch panels. But these connectors in loaded panels are often permanently mounted, so if a port gets damaged it’s dead forever. Unloaded patch panel, on the contrary, is more flexible that can let you swap out defective ports at will. But extra assemblies are demanded to be purchased and installed by yourself.

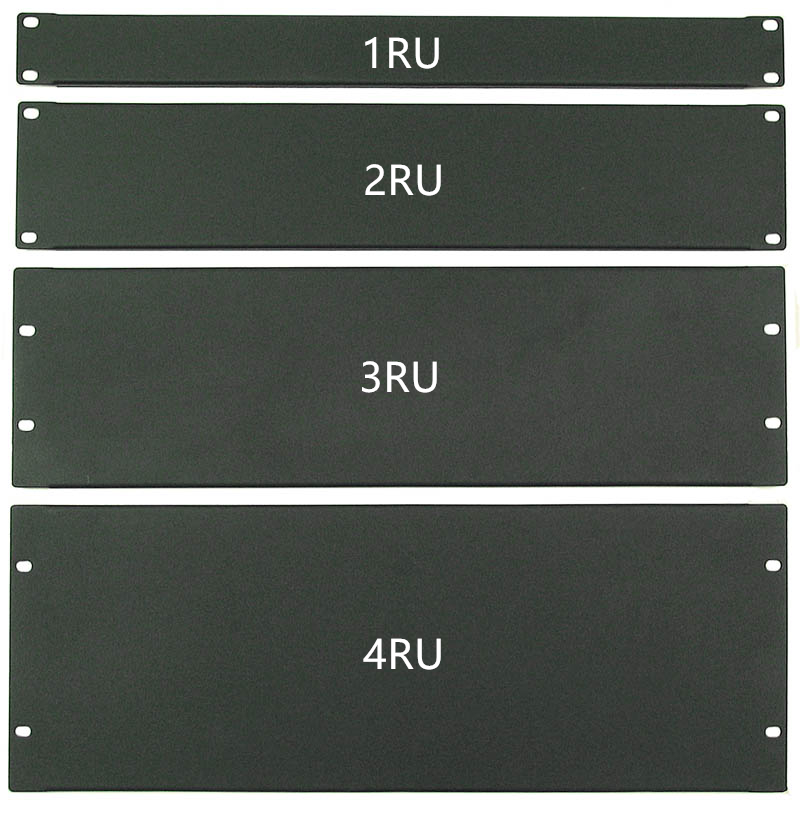

Fiber patch panel is usually measured by rack unit. A rack unit is used to describe the height of electronic equipment designed to mount in a 19-inch wide rack or a 23-inch wide rack. The height of rack-mounted equipment is frequently described as a number with U or RU. 1U refers to one rack unit, 2U refers to two rack units and so on. 2RU and 4RU are often used for high-density installations. So according to your application, the related rack size should also be adjusted.

Port density is also an important part to be considered when purchasing fiber patch panels. As for normal patch panel, 1RU is able to carry 48 ports. If high-density patch panel is required, 1RU can support 96 ports. Moreover, 144 ports in 1RU is also available with ultra density patch panels. Since high-density has been frequently applied to the data centers, patch panels with higher port density becomes the future trend.

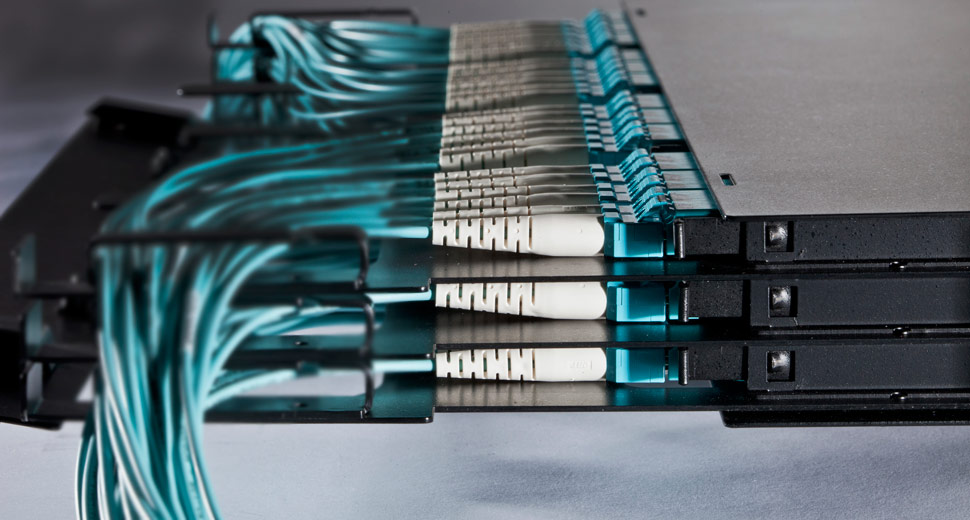

Nowadays, people are paying more attention to the 40G and 100G high speed networks. MPO/MTP breakout patch panel may be an ideal solution for this high-density installation. Deploying high-density patch panels has many advantages. It simplifies the cabling deployment by running a short fiber patch cable from your SAN or network switch up to the fiber patch panel. Much space can also be saved in data centers by mounting more cables into a smaller space. Installation is easier since no tools are required to install cassettes in the patch panels, and push-pull tabs are used to ease the difficulty of cable connections in the patch panels. After all, high-density patch panel is a cost-effective solution that overcomes the cabling congestion in high bandwidth networking.

The well-organized and well-protected cables are the guarantee of a stable network. Fiber patch panel is definitely the perfect solution that meets all the requirements. Choosing the right fiber patch panel is also beneficial to your network. You may consider from the aspects of loaded or unloaded types, rack size, port density, etc. In addition, high-density fiber patch panel is welcome by the 40G/100G network. If you want to achieve better high bandwidth application, patch panels with high-density ports are recommended.