The term “punch down” is used for the physical force needed to pierce or take away the cable insulation while the connection is being made. Punch down tools or krone tools (named after the Krone LSA-Plus connector) are widely used for copper network built by Ethernet cables including cat 5, cat 5e, cat 6, etc. As we know, these copper cables can be connected with keystone jacks, cross-connect blocks, patch panels and surface mount boxes. Therefore, the function of punch down tools is to insert the wires into the IDC (insulation-displacement connectors) on these terminations. This post is going to introduce some basic knowledge about punch down tools and the proper way to use them.

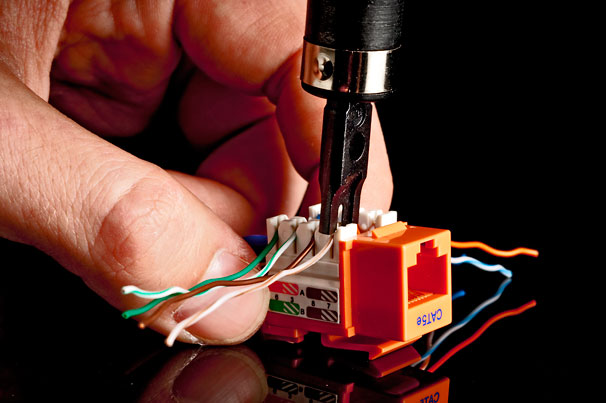

Many punch down tools are composed of a handle, an internal spring mechanism and a removable slotted blade. After positioning the wire into a slotted post on a punch down tool, just pressing down the tool on top of the wire over the post. Then the internal spring will be triggered by the required pressure and the blade pushes the wire into the slot. At the same time, the blade cuts the insulation and secures the wire.

Step one, make preparations before punching down a wire. When gripping the punch down tool in one hand, you should ensure that the cutting blade is facing down. Then coil the wire through the connection block terminal by another hand.

Step two, punch down the wire. You should firmly hold the wire’s end in hand and set the tool’s blade on the selected connection terminal. Then pressing the tool forward with a straight move until reaching the bottom of terminal. If you are doing it right, any excess wire would be cleanly cut off and the remaining wire would be easily connected to the terminal.

Step three, check the wire connection. Make sure the connection is secure and no broken or loose wire is left in the connection block. You can test to see if the wire is indeed fastened securely to the right terminal by tugging on it.

Tip one, always wear safety goggles or glasses when using the punch down tools. Because small pieces of wire will fly in all directions during the punch down process, which is a potential risk to your eyes.

Tip two, if the wire slips out of the connection block, you can use a flat head screwdriver to slightly increase the pressure applied by the punch down tool.

Tip three, if using the highest pressure setting, the tool still cannot cut through the cable. Then the cutting edge must become dull. This means that you need to replace the blade with a new one.

Tip four, do not use a punch down tool to tighten up flat head screws as this can break or shatter the blade.

Tip five, though most models are made of plastic, punch down tools can still conduct current. Keep this in mind when working with electrical circuits.

Tip six, you should always carry at least one extra blade for each type of termination that you are doing. Blades don’t break often, but they do break occasionally.

Tip seven, a 4” square of carpet padding or mouse pad makes a good palm protector when punching down cable on modular jacks.

Punch down tools are usually applied to data or telecom network wiring in computers, phones and audio devices. Of course, many types of punch down tools are available to meet different requirements. Good tools even have replaceable blades. Employing punch down tools greatly accelerates the working efficiency and reduces the task difficulty. It is important for technicians to use them in daily applications.